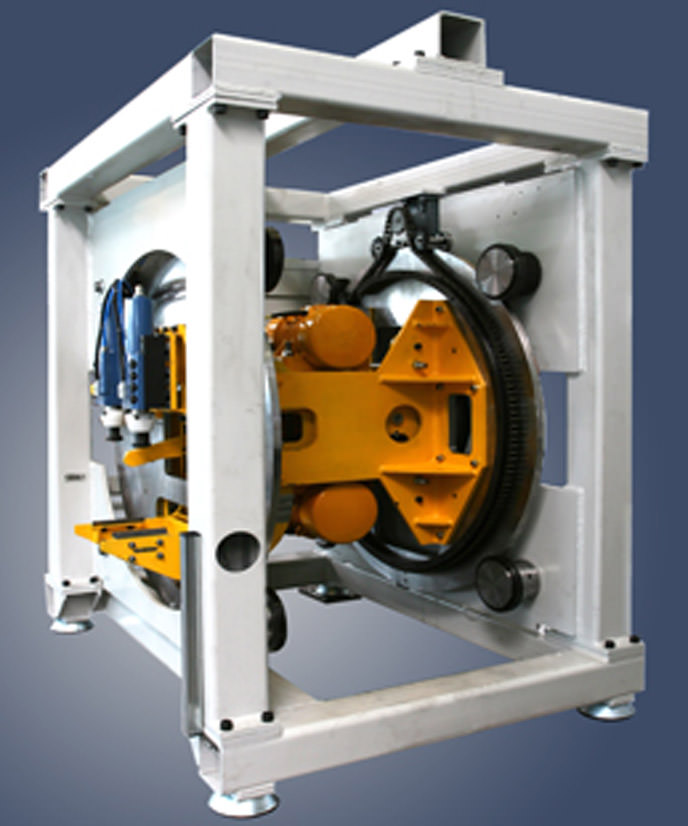

The Mössner decoring cell adapts to the individual cast part, and even in mixed operation enables its thorough decoring in connection with automatic part recognition. The high-performance decoring box is automatically loaded and unloaded robotically. Sand cores and sand which is stuck on is released by electrical and hydraulic knocking, vibration and swivelling apparatus, and is then shattered and shaken out. The individual decoring operations which are adapted to the cast part can be varied and programmed. The decoring time depends on the cast part. For two cylinder heads, for example, it is approximately 46 seconds for double loading.

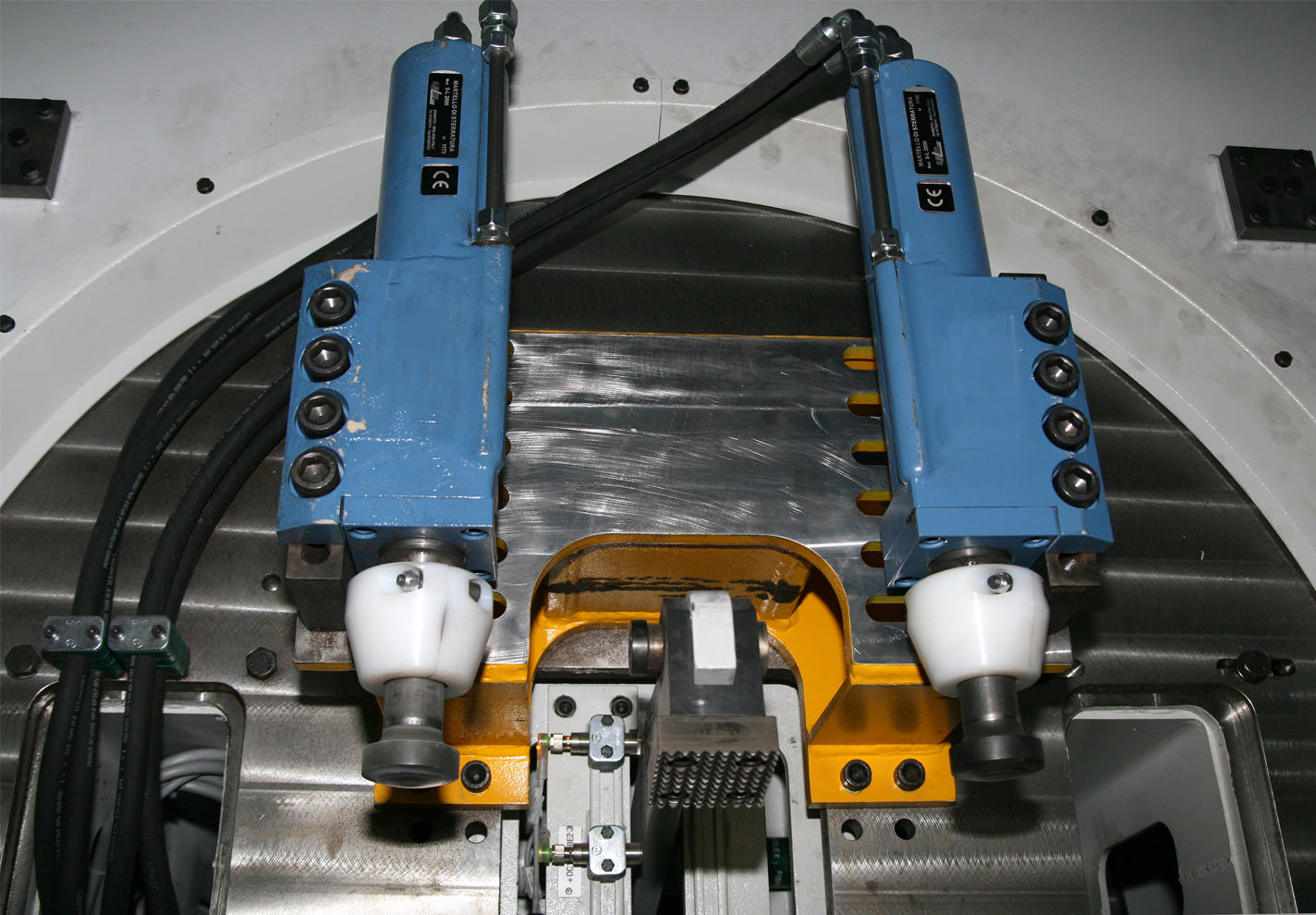

The decoring box is noise-protected (noise emissions: < 80dB(A)) and has loading doors which open and shut automatically. The sand is removed under the floor on a transport belt. An air removal rate of approximately 2000 m³/h is required to remove dust from the air. The sand cores are then shattered by way of pneumatic knocking operations, are ground through electrical vibration apparatus and are then transported out of the cast part. The emptying process is aided by the rotation of the cast part. The decoring system has two hammers and can optionally also be equipped with four hammers.