With the help of contour saws from Mössner, we bring your blanks as close as possible to the final contour. The so-called ‘cut to size’ or ‘near to shape’ makes it possible to significantly reduce the amount of subsequent machining required thanks to our advanced sawing technology. This means that more recyclable material is retained, which conserves resources and reduces the costs of your cut-to-size parts in the long term.

The Mössner band saw machines for contoured cuts can be controlled numerically (X axis) and can be rotated numerically about the saw cut line (C axis). Through the numerically controlled delivery of the workpiece (Y axis), any contours can be sawed in plates and blocks. The coordinate transformation for the current calculation of the three axis values (X, Y, C) is carried out directly in the control system and allows simple contour programming with XY coordinates. Additional features are, for example, a fully automatic part supply system, a waste and chips disposal system, a compacting system, a part transport system and a protective cabin.

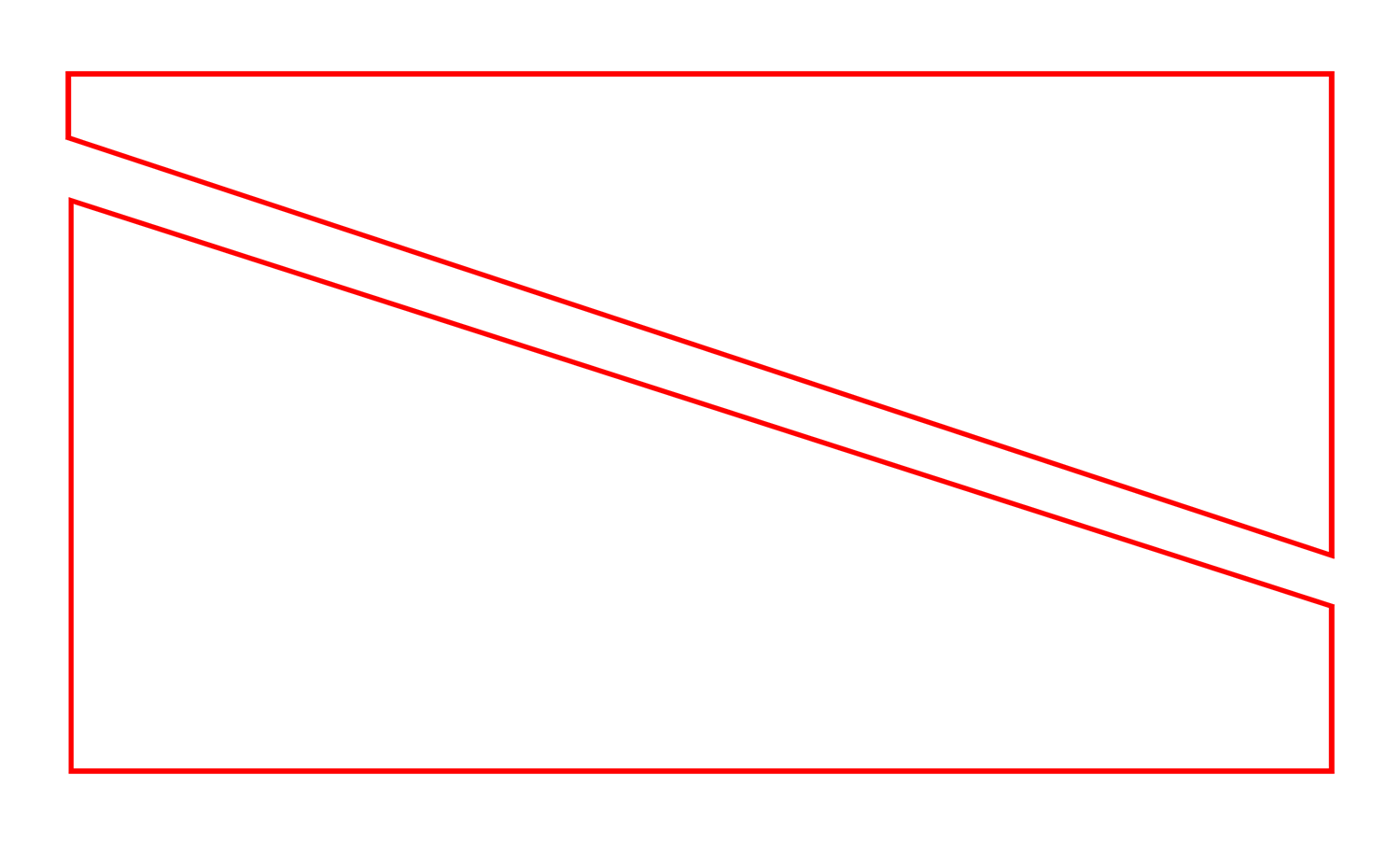

Typical process:

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren