February 2024 –

3D scanning at Mössner

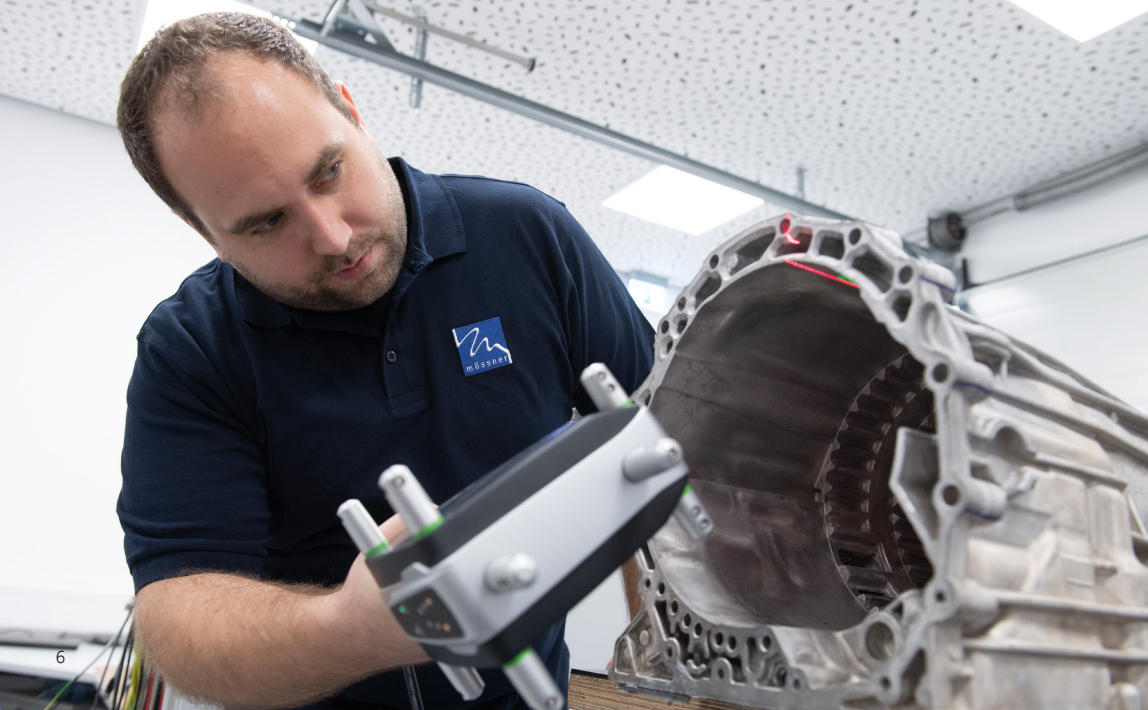

When machining cast parts for well-known car manufacturers, robots have to demonstrate maximum precision. But deviations from target production data make gripping difficult. This is where the innovative application of ZEISS T-SCAN comes into play: customised moulded parts for robot grippers are produced with this high-precision laser scanner, not only to optimise the gripping of cast parts, but also to simplify the programming of the systems.

Christian Kunz our general Manager, provides insights into how the team successfully overcomes challenges with tolerances in cast parts. By precisely measuring the surface contour of cast parts with ZEISS T-SCAN and comparing it with the car manufacturer’s target CAD data, moulded parts can be optimally adapted, and the robots efficiently programmed.

The flexible complete laser scanning solution not only saves a considerable amount of time, but also enables more precise programming of the automated production systems. Thanks to ZEISS T-SCAN, August Mössner can accept systems up to two weeks earlier, which is particularly important for series start-ups in the automotive industry.

Find out more about the pioneering application of ZEISS T-SCAN and the impressive results in practice.