February 2021 – Short update about our ongoing project

🔧💪🏻

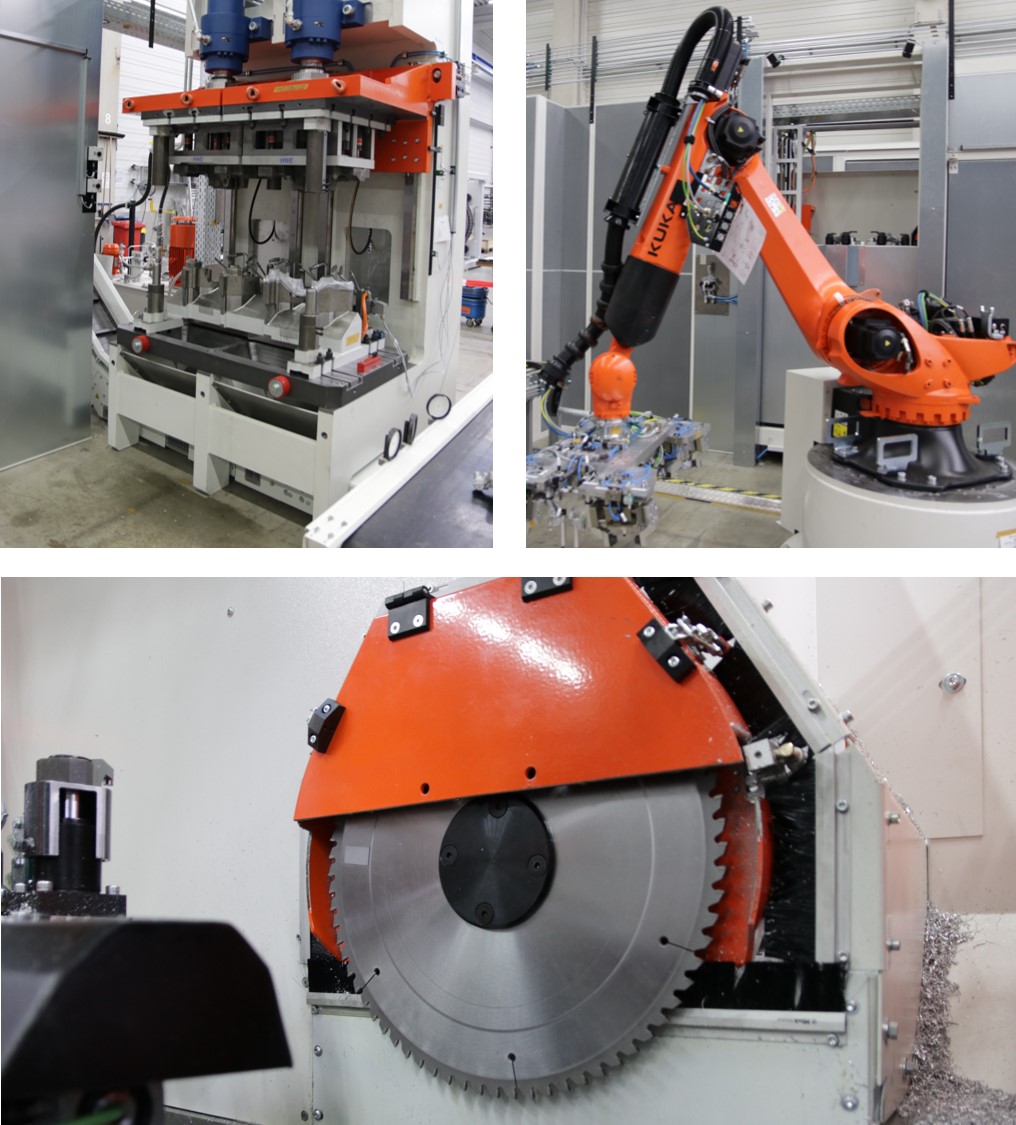

With a cycle time of 57 seconds, wheel brackets are cut and deburred in this system. A robot takes over the handling of the workpieces.

Deburring is done on two of our special presses. Standard hydraulic components, power units, valves and cylinders enable a favourable lifetime and facilitate maintenance. The driven tools are optimised for fast loading and unloading by a robot. Burrs are transported on a conveyor belt into a container.

A special circular saw station with two circular saws and two servo-controlled axes separates feeders and sprue systems. Accumulating chips and circulating material are transported out of the saw by a conveyor belt and then separated.

An X-ray machine, which is also loaded and unloaded by the industrial robot, is used for quality control. Workpieces that do not meet the quality requirements are discharged on a belt conveyor.