For the dismantling of nuclear facilities, we take on not only production orders but also the development of individual components and complex systems technology. We also offer testing, assembly and service for our systems technology. To make this possible we provide radiation-exposed personnel (category A) in assembly, project management and development to enable commissioning and service on site.

Our machines and systems are used for dismantling and packaging of medium and high radioactive material. These are for example stainless steel cases, core shrouds, cast rings, primary shielding, steam generators, primary plates, reactor pressure vessels and other large components.

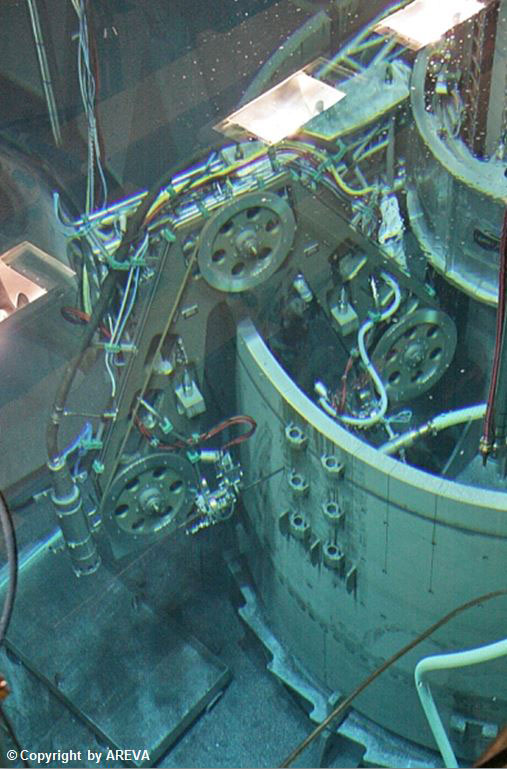

The systems technology can work completely under water and in dry areas. Remote handling of the system and the handling systems is also possible.

We offer

Projects already:

References

Mössner developed a special underwater saw with turntable and clamping equipment for the decommissioning of nuclear devices at the nuclear power plant in Rheinsberg.

With the use of one of our underwater band saws, nuclear devices were dismantled in a nuclear power plant in Lubmin.

Mössner developed a special band saw for the dismantling of cast rings and other large components for the purpose of decommissioning the experimental reactor in Rossendorf.

Mössner developed a band saw machine for the decommissioning and packing of the primary shielding at the compact sodium cooled nuclear reactor plant in Karlsruhe (KNK).

With the means of a band saw developed and built by Mössner, the cutting of a core shroud and its components was carried out in Stade. The work was carried out completely under water.

The decommissioning of stainless steel transport cases is carried out in a nuclear power plant in France with a special sawing system developed by Mössner. The decommissioning takes place in a dry environment.

Mössner supplied transport racks for new fuel elements for a nuclear power plant in Grohnde.

We developed and delivered a lock car for the transport of castors with spent fuel elements from the wet storage in Obrigheim.

Your contact for Nuclear Decommissioning