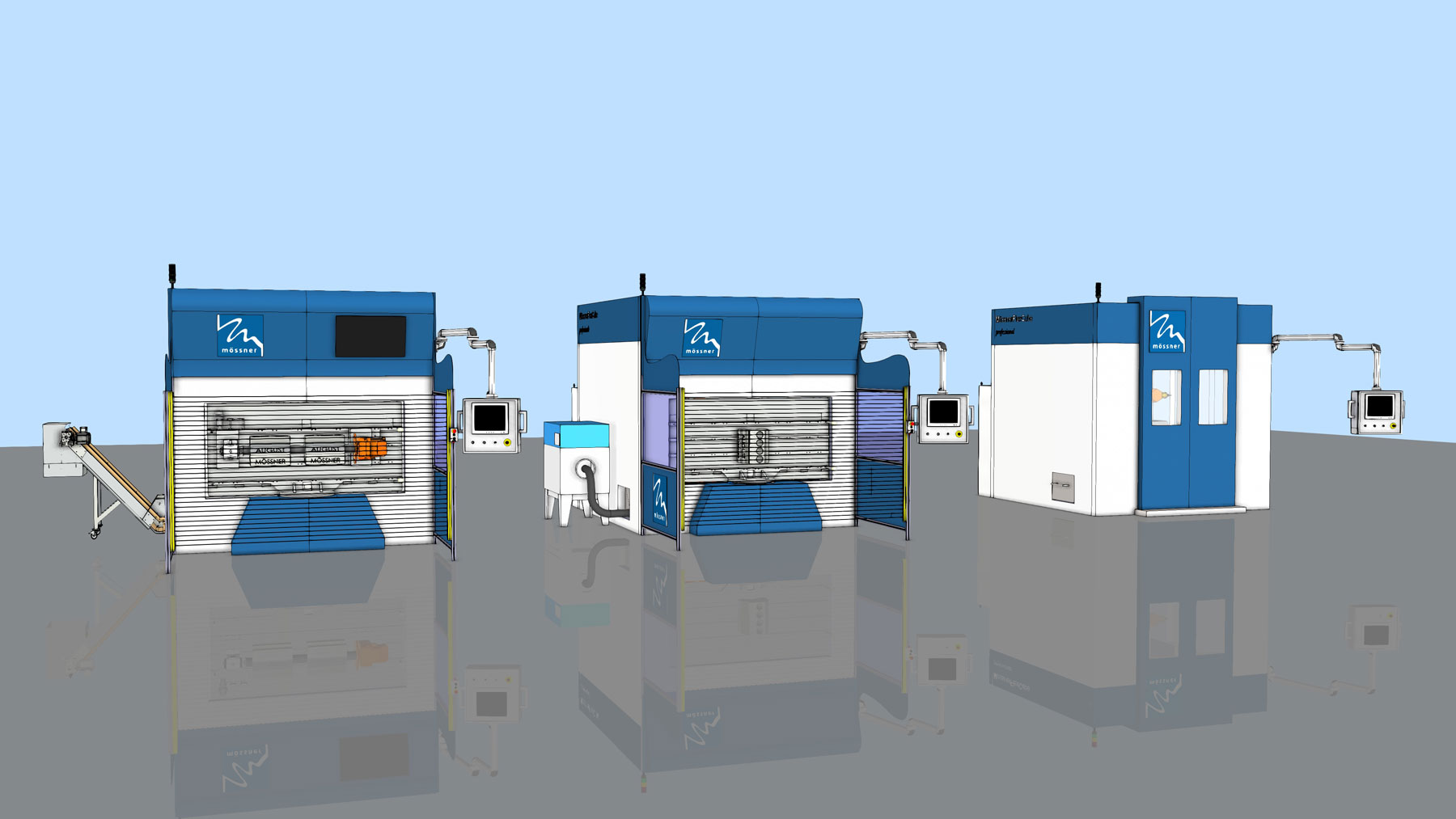

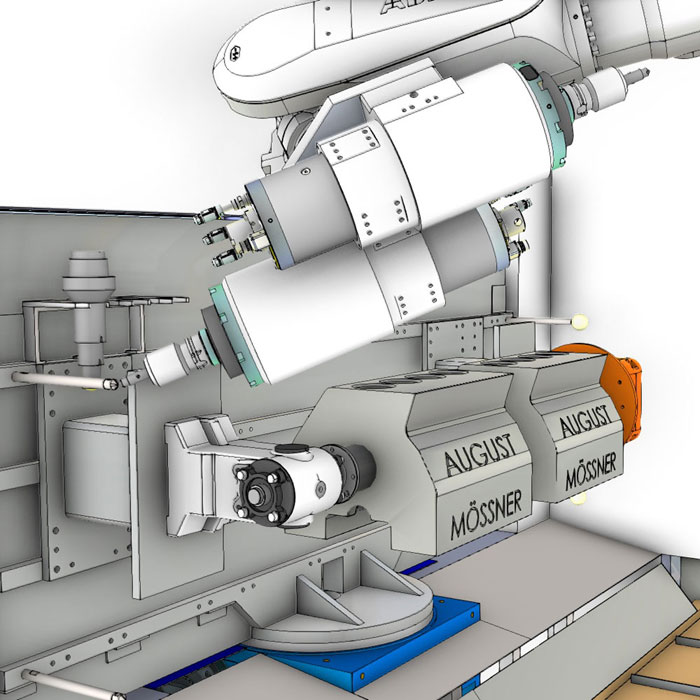

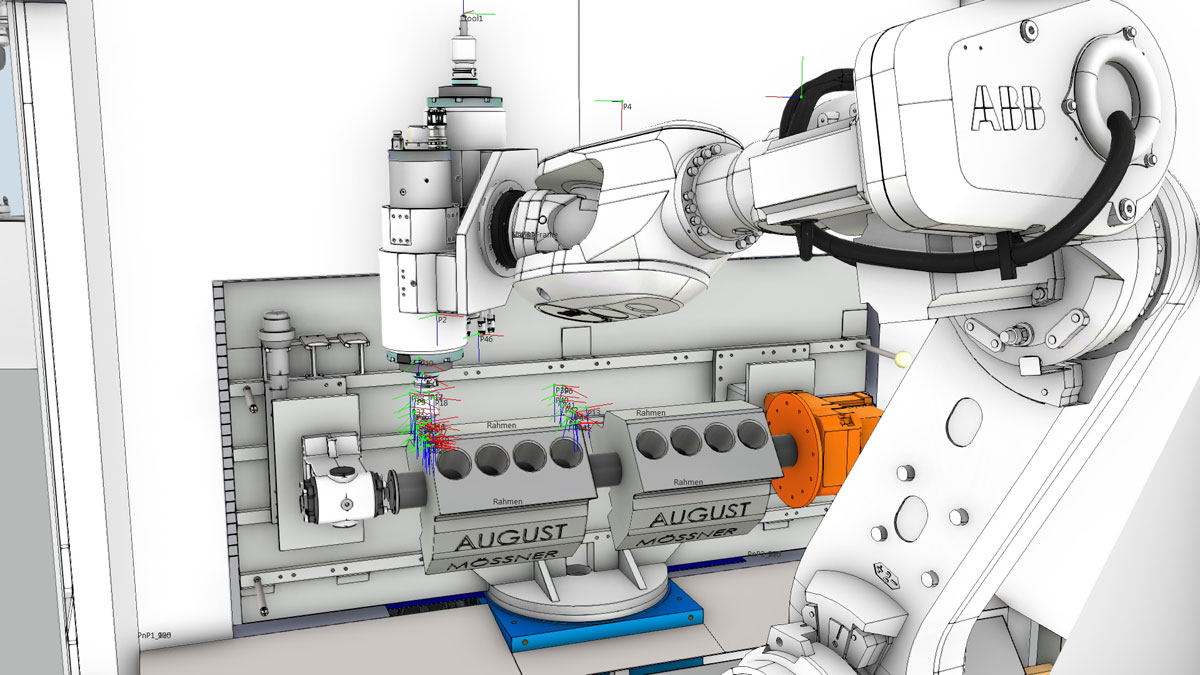

With our decades of experience in robot-guided processing, with our Mössner FlexCube we provide a flexible processing cell as a cost-effective alternative to a CNC machine. The modular design of the processing cell offers a tailor-made solution for your requirements. At the same time, it allows easy exchange of the modules when requirements or workpieces change. The Mössner FlexCube leaves nothing to be desired for your production processes, whether used as a tool-guided milling cell, deburring cell or grinding cell.

The robot cell is divided into configurable modules which are largely independent of each other and easily interchangeable. The following modules of the robot processing cell can be configured:

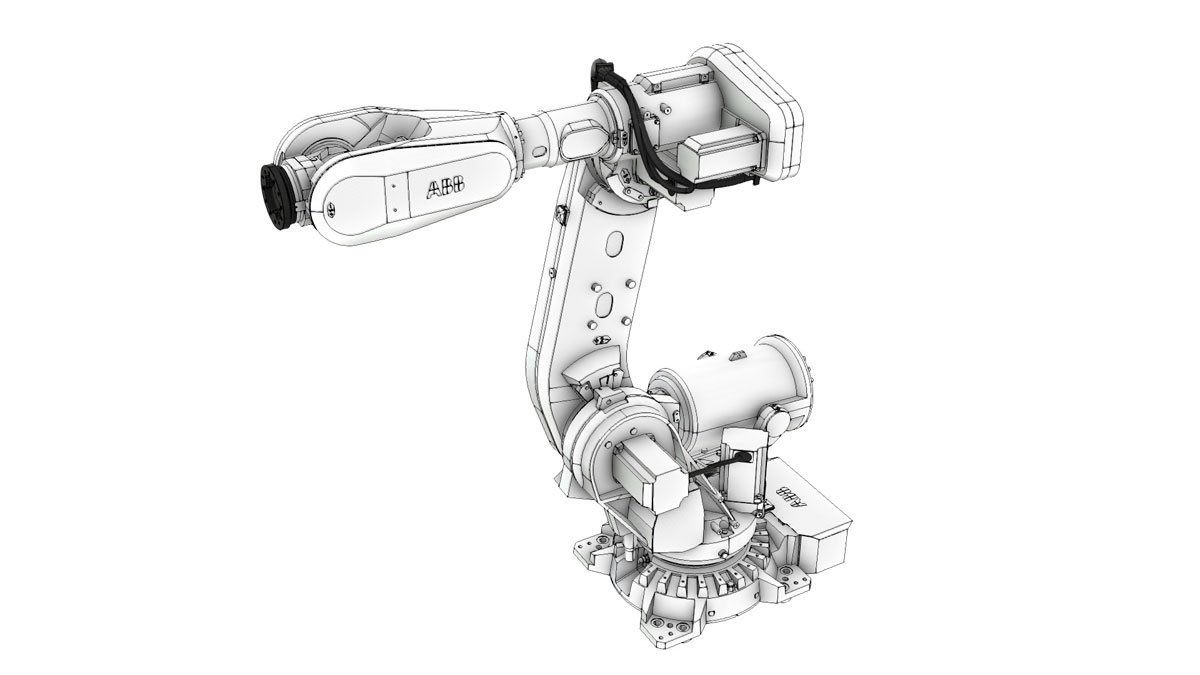

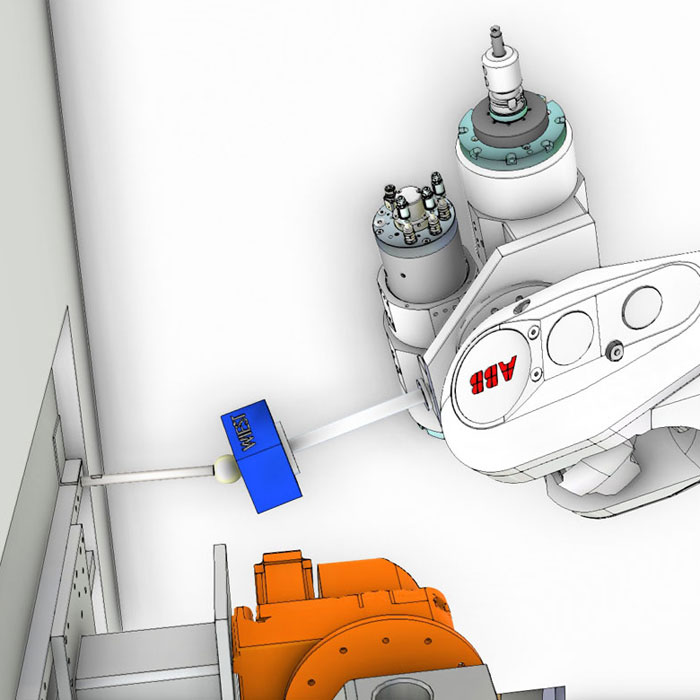

We offer you maximum flexibility when choosing robot manufacturers such as ABB, Fanuc and KUKA. Different robot flange loads are available to suit the processing tasks. The modular design enables subsequent changeover between the robot sizes. We also offer additional option packages for the various robots, such as the foundry version for particularly harsh environments or industrial robots with precise measurements.

When choosing the manufacturer ABB following industrial robots are available:

When choosing the manufacturer Fanuc following industrial robots are available:

When choosing the manufacturer KUKA following industrial robots are available:

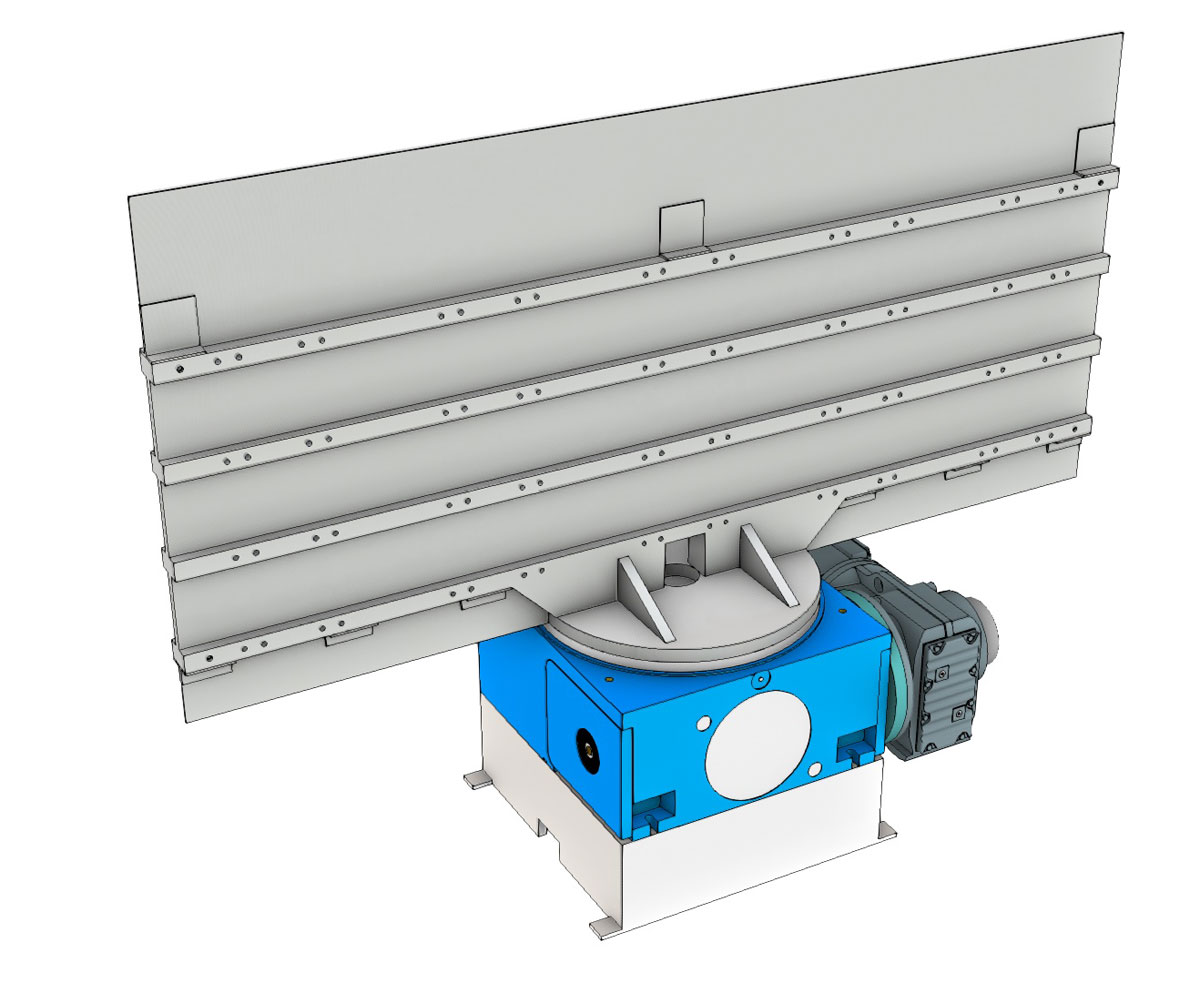

Whether for individual or series production – we have the right fixture to suit your workpieces. You can choose between a worktable with manual loading for individual or prototype production and a rotary table for series production with optional, flexible attachment of positioners for all-round processing of workpieces. The positioners from the manufacturers ABB, Fanuc and KUKA depend on the robot selection. Manual, pneumatic and hydraulic clamping of the workpieces are available.

Worktable with 1700 x 1000 mm screw-on surface for maximum flexibility when attaching workpieces.

Rotary table for workpieces up to a size of 2000 x 1000 mm. A hole pattern allows the flexible arrangement of the workpieces.

The special hole pattern offers flexible mounting of positioners on the turntable. With different flanges it is also possible to mount the positioners in different axial directions. Horizontal mounting is possible with workpieces up to a size of 1200 x 800 mm.

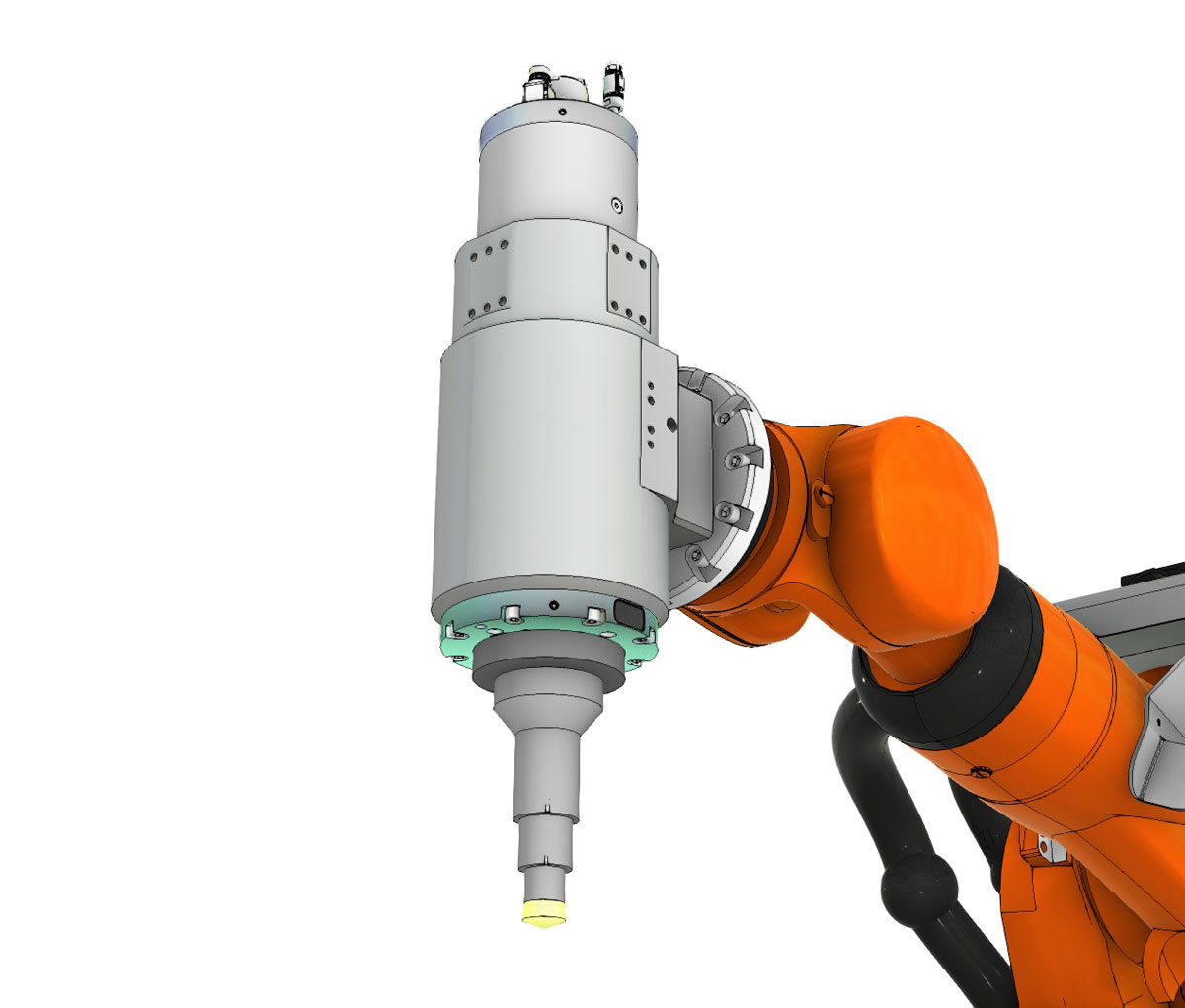

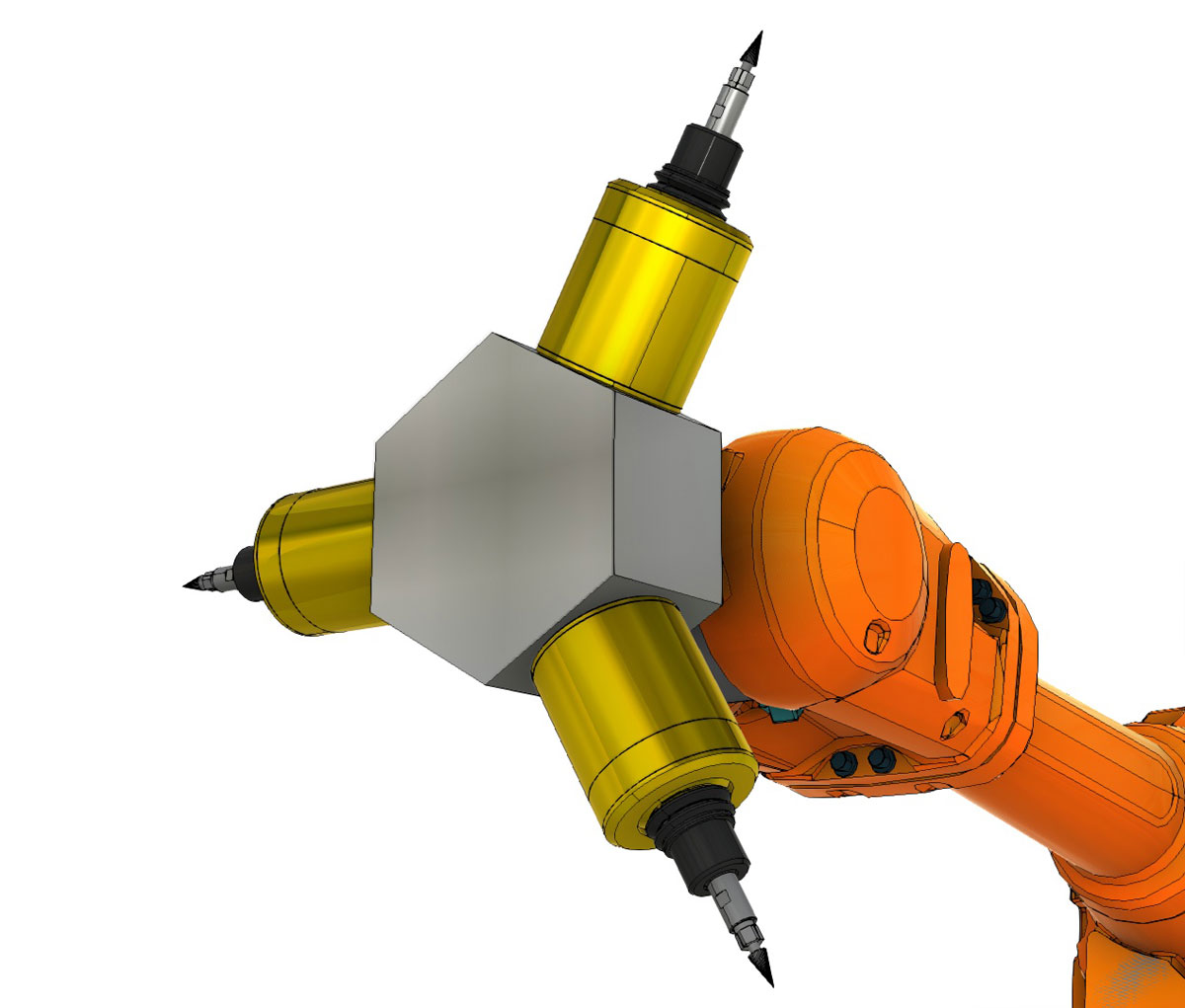

We offer a wide range of different processing spindles to choose from. From motor spindles to belt and pneumatic spindles in various performance classes. Thus no machining wishes remain open. In addition, there is the possibility of multi-spindle versions to avoid tool changes.

If several tools are required, it is possible to install a tool changer. With the turntable version, the tool change is possible during production.

When choosing your tools, benefit from our many years of experience in the robotic finishing of castings, such as die casting, steel casting, gravity die casting and sand casting. Whether for workpieces made of aluminium, brass, steel, cast iron, plastic or fibre composites – we find the best possible tool including tool system for you.

Due to tool-guided processing, other tool systems such as an adhesive head, polishing attachment, tape laying head or hammering attachment are also possible.

We would be pleased to advise you about the possibility of other tool systems.

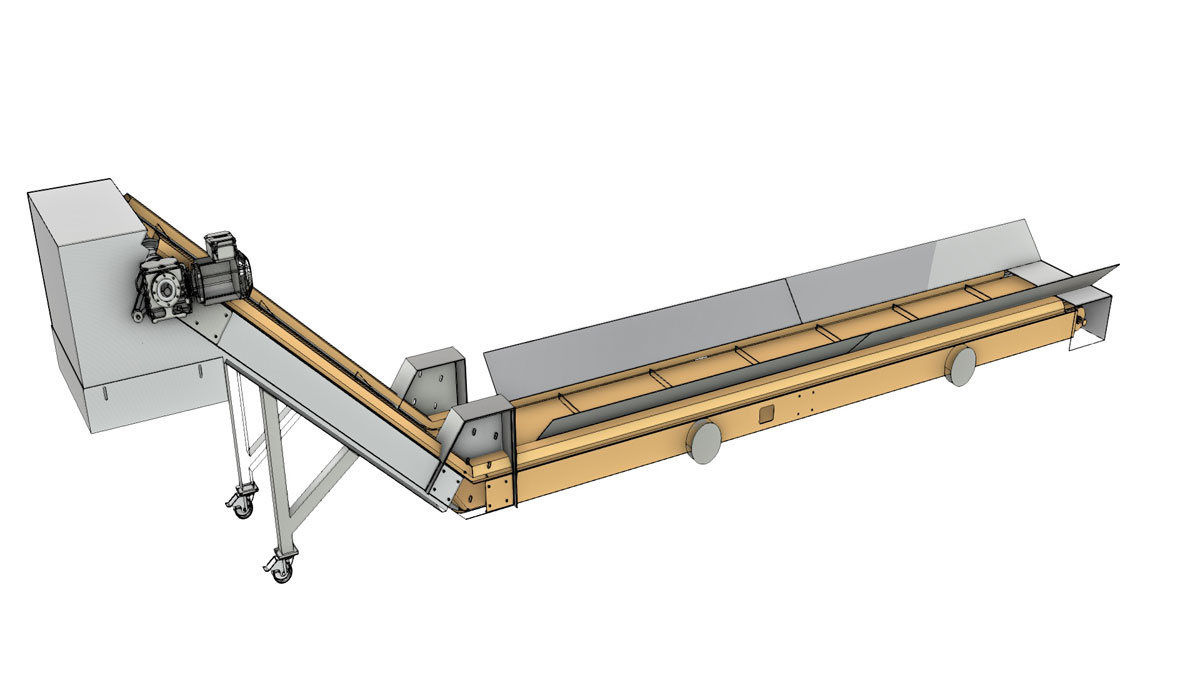

For chip disposal we offer you the possibilities of chip trays, suction systems or chip conveyors. If requirements change subsequently, the modules can be exchanged at any time. Thus the robot cell offers maximum flexibility regarding chip disposal.

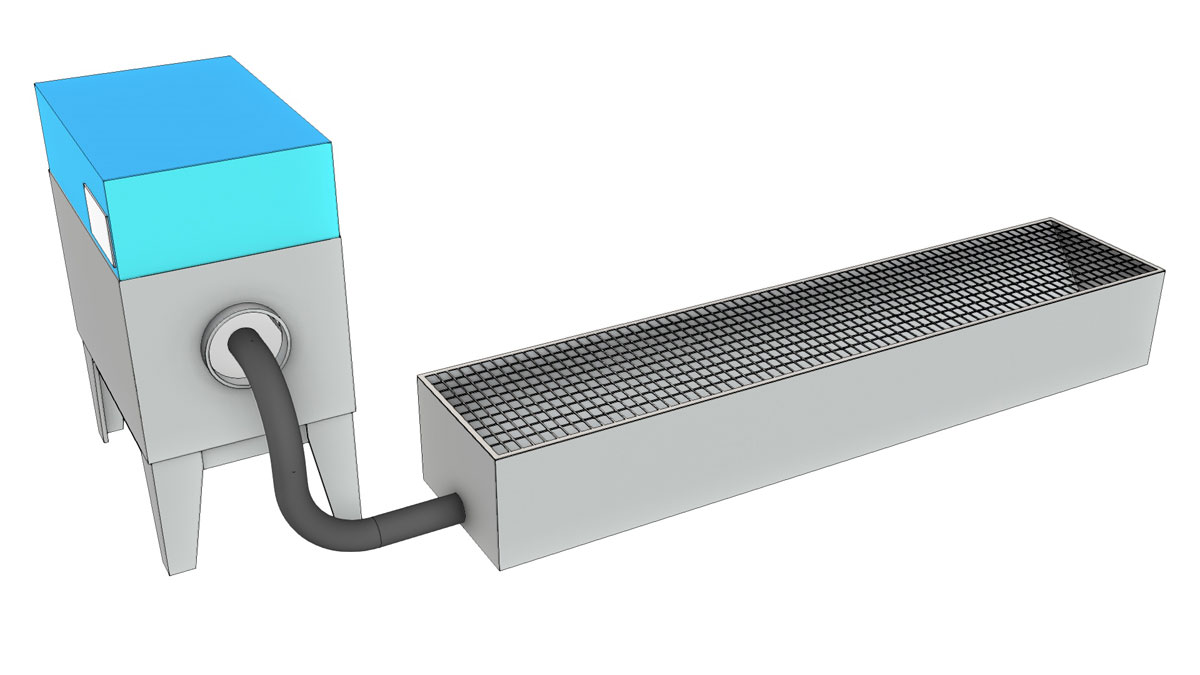

The chip tray, as a cost-effective universal solution, offers a large collecting area for the most diverse materials and machining processes. The chip tray consists of two parts, which can be removed sideways and emptied separately by opening the locking device.

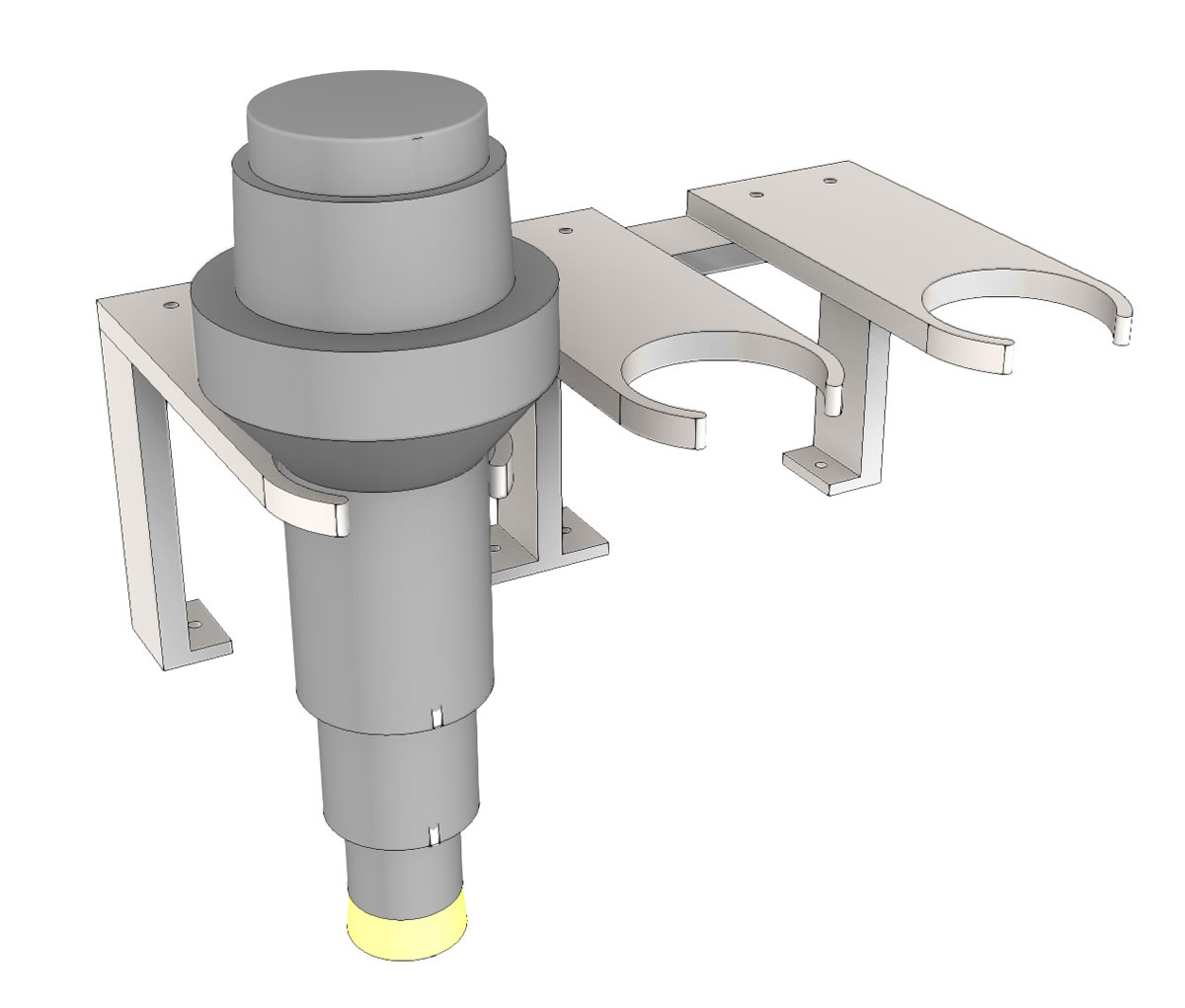

The suction system is the perfect solution for small chips, for example when using minimum quantity lubrication. Due to the attached protective grid, even separating tasks with larger separation residues are possible, considering manual removal of the separation residues.

Chip conveyors remove the majority of all types of chips and residual material. Chip conveyors are therefore considered to be a universal solution for almost every machining process.

The basic framework consists of the sound enclosure and the base plate. The base plate connects the industrial robot, the tool system and the workpiece holder and can be transported as a forklift-compatible complete assembly. The modular design of the base plate makes it suitable for all robots as well as workpiece fixtures, thus enabling replacement or upgrade to another system.

The sound enclosure is available as short version for the ~60kg robots and as long version, suitable for all robot sizes.

If the worktable is selected for workpiece fixture, the access area of the cell is designed with sliding doors. If the workpiece is inserted via rotary table, the worker is protected by light curtains.

The modular (plug and play) design allows a quick and uncomplicated assembly of the processing cell.

Mössner FlexCube professional

The professional version is ideal for deburring tasks. Smaller parting lines or flashes can be removed without problems.

Mössner FlexCube professional+

The professional + version is ideal for deburring and smaller milling tasks. Larger parting lines or flashes can be removed without any problems.

Mössner FlexCube high professional

The high professional version is ideal for milling tasks. Larger burrs such as parting lines or sprue residues can be removed without any problems and smaller amounts of material can be removed. In the same manner, the separation of feeders is possible by integrating saw blades or cutting discs.

Other possible options include tool measurement, measuring procedure for workpieces and tools as well as processing monitoring. Furthermore, with the integration of camera-based recognition systems, various components can be seamlessly processed.

Further information Image Processing

Robots and workpieces are calibrated by measuring tips as standard. This can be replaced by a high-precision laser calibration system on request.

Benefit from a digital twin of your plant, already during the preparation of the offer, which makes it possible to carry out a feasibility and cycle time analysis of your parts in the shortest possible time via simulation.

The option package Service includes services such as programming the robot processing, training with the robot processing cell or preliminary test series of your workpieces.

In this way, the robot machining cell becomes a turnkey solution when pre-programming is selected, which is ready for production immediately after installation.

Your contact for the Modular robot processing cell MFC