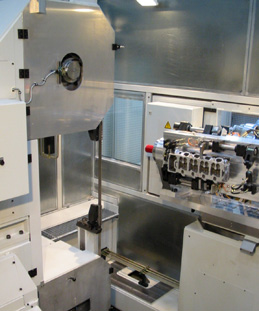

Our bandsaw machines with NC axes carry out their feed movements directly at the machine. They are available as semi-automatic bandsaw machines with manual loading or with robot-guided loading and unloading.

There are two types of band saws:

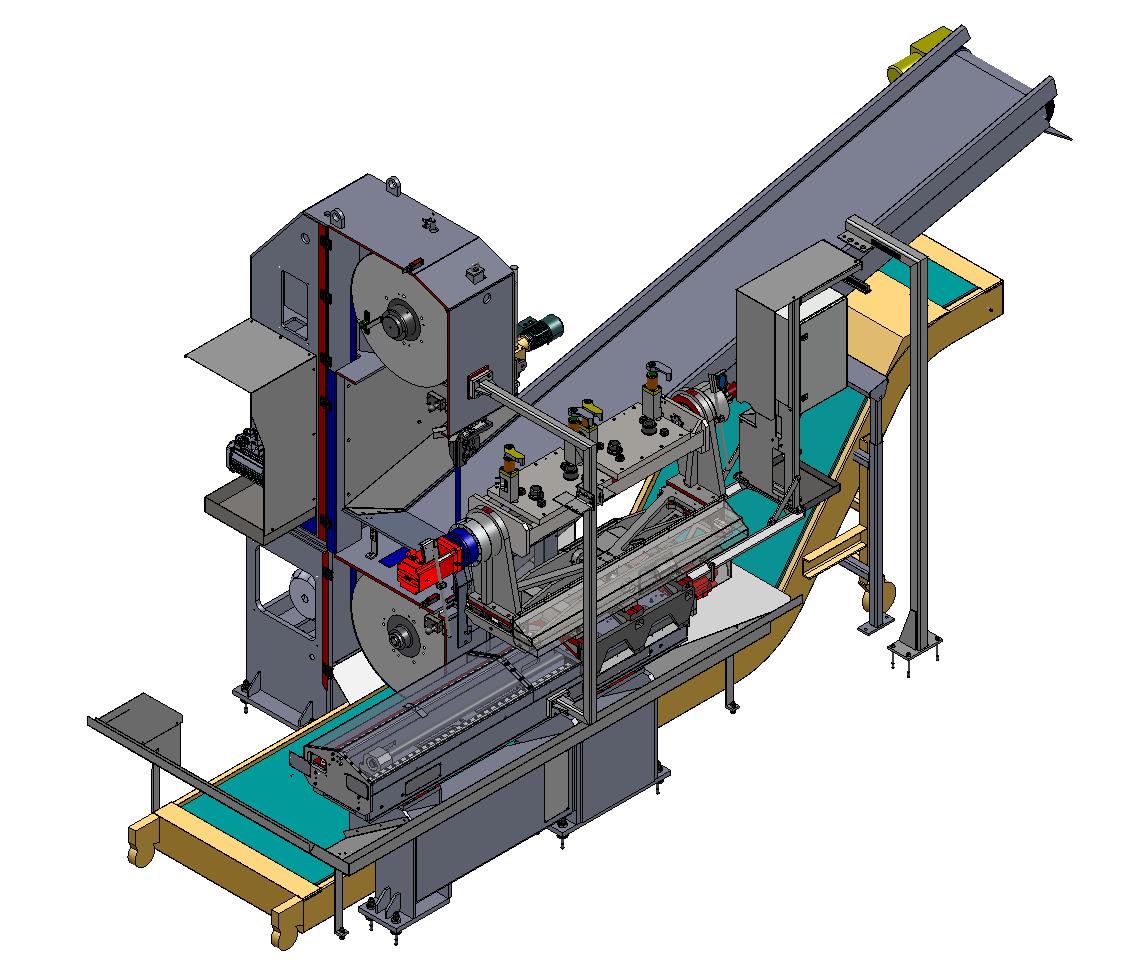

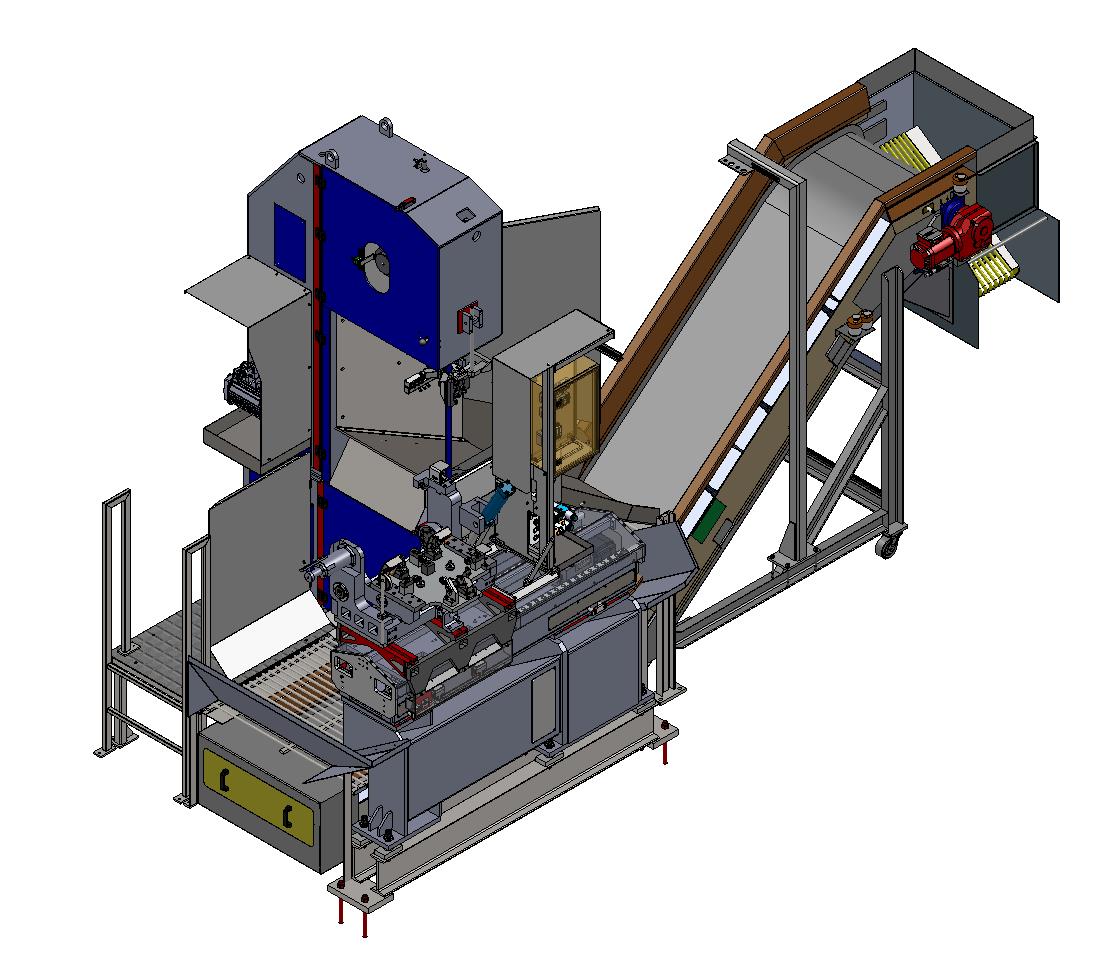

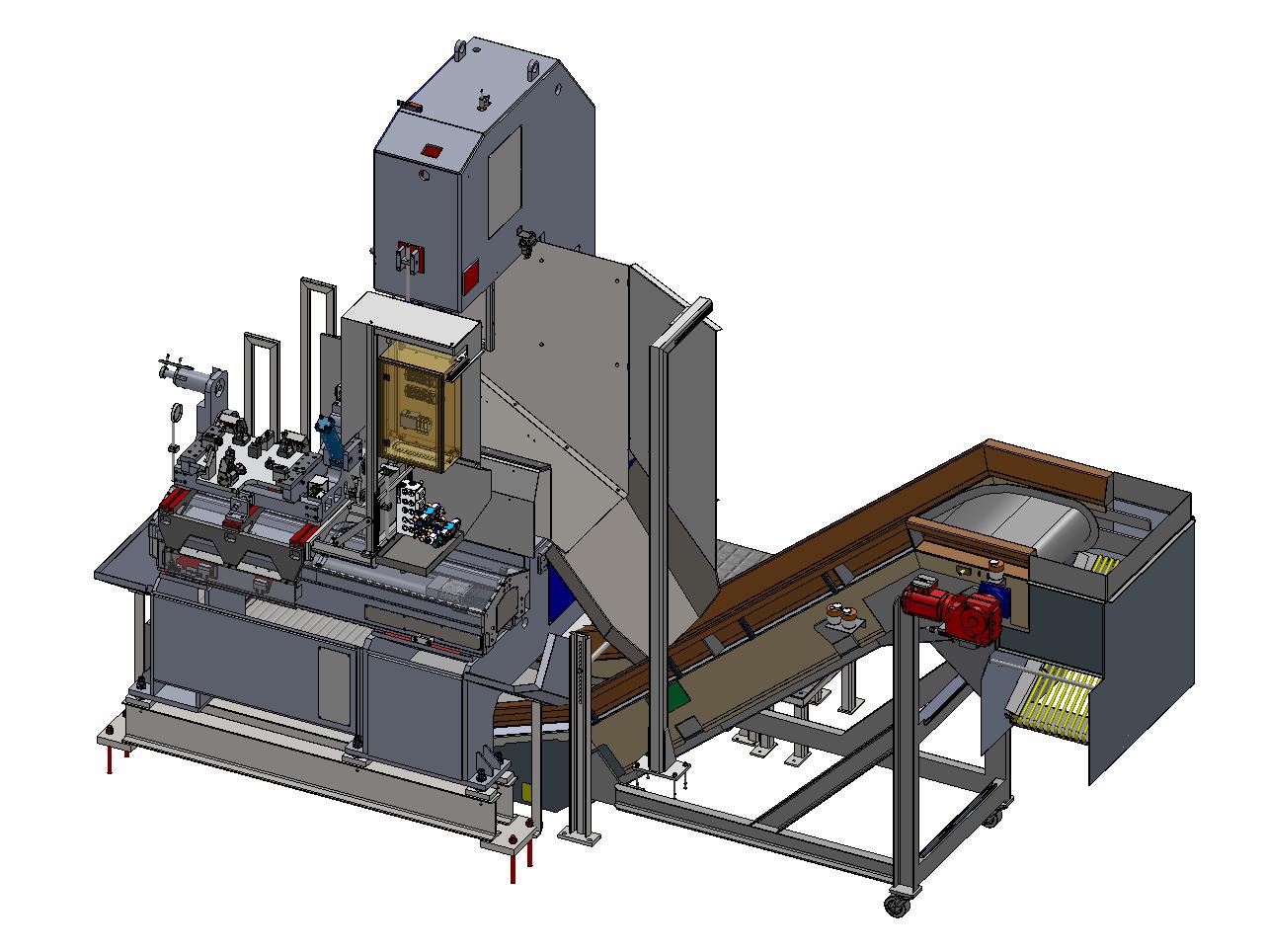

When the workpiece holder is fixed, a rotary table guides the workpiece to the sawing position. The bandsaw then moves to the machining position and carries out the sawing operation. Meanwhile, the already processed workpiece can be unloaded on the other side of the rotary table. This reduces downtimes during the sawing process to a minimum.

The feed unit is mounted on an NC axis, which moves the workpiece along the saw band and separates the feeder from the casting run. On request, we can integrate additional axes in order to be able to turn the fixture additionally. This enables easy loading and unloading by the robot. It is also possible to attach up to four workpiece-specific fixtures to the saw. This makes an automated set-up possible. Any chips and risers are transported by conveyor systems into appropriate containers.

Our saws are equipped with

Our saw blade guides, and the adjustable guide arm ensure perfect positioning of the saw blade. This results in a precise cut with maximum saw blade life. The hydraulic band tensioning system automatically sets the correct band tension and keeps it constant during operation. Bandsaw blade positioning aids allow quick and safe changing of the saw blades.

Your contact for sawing