Traceability and component identification are important requirements in the production process. We offer various solutions for seamless component tracking, such as needle embossing, laser marking and reading OCR codes.

Learn more on the subject ID readers:

Needle embossers are used particularly to apply robust codes which are still readable for example after a blasting process. Contrary to laser marking, no exhaust systems and laser-safe cabins are required.

With our marking stations, data matrix codes, 2D code markings, single dot markings and plain text can be applied. The marking stations can be loaded and unloaded with a robot. The marked code is then read by ID readers. Verification of the codes is also possible.

Our marking lasers are available as ready-to-use stations to integrate into your machines and systems. With marking lasers, it is possible to apply various codes, logos, plain text, 2D codes, barcodes and data matrix codes.

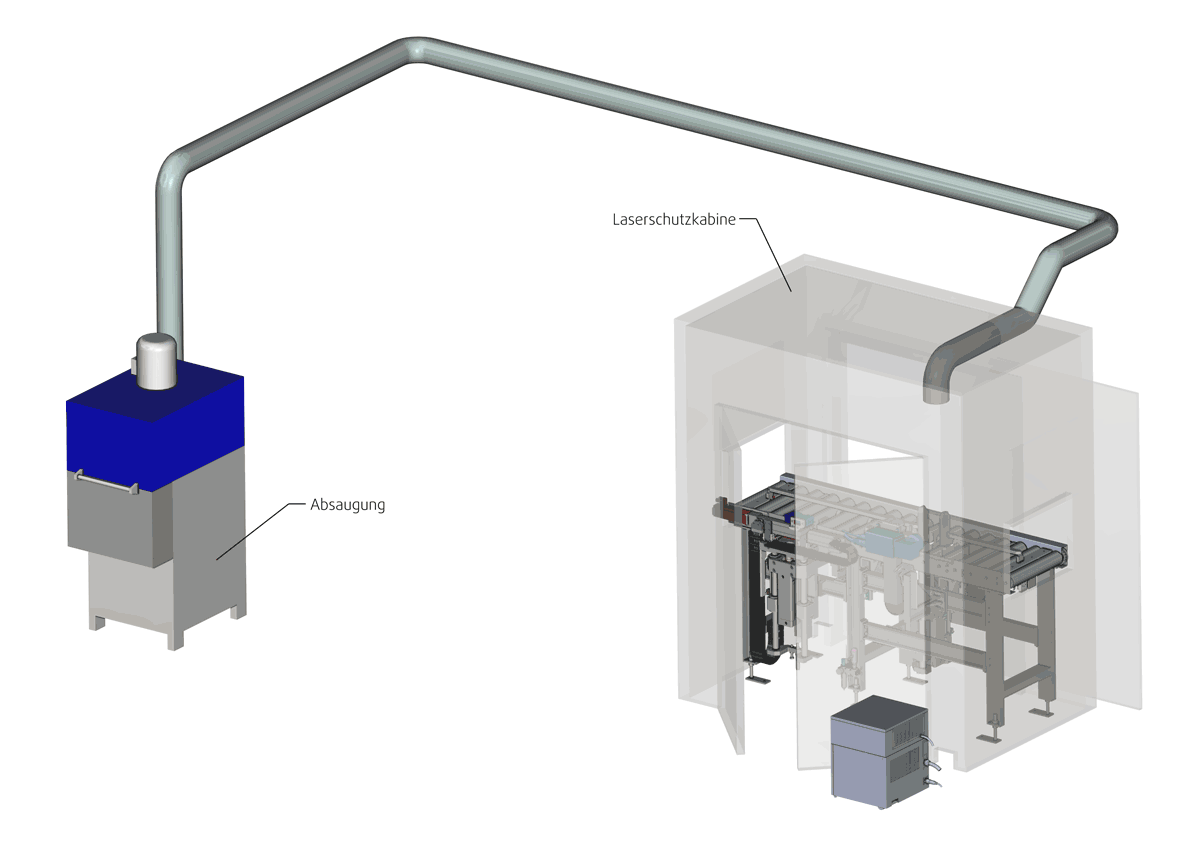

Laser marking requires special protective cabins and extraction. These are available from us as turnkey solutions. The marking stations can be loaded and unloaded by hand or by robot. Our RunThroughMark is also available as a continuous system with a cycle time of 25 seconds.

Learn more about our different types:

RunThroughMark

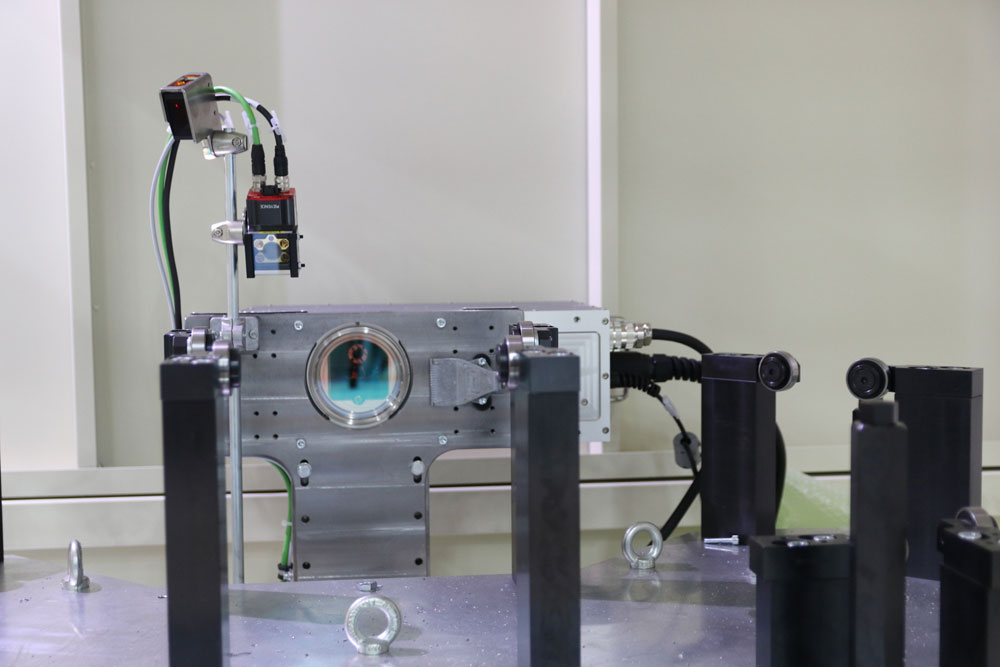

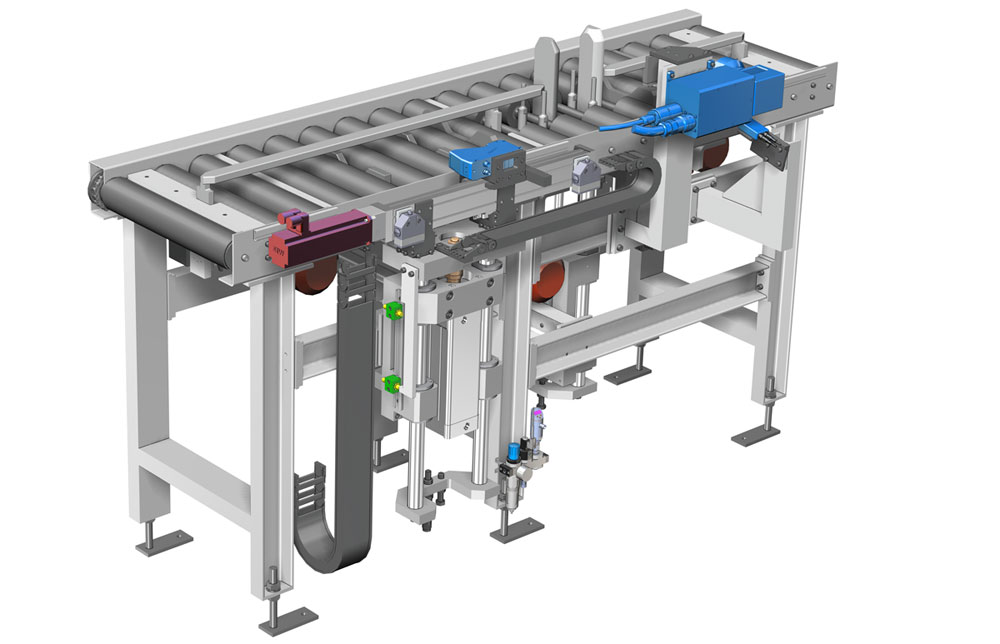

With our RunThroughMark the workpiece is transported on a transport system. The workpiece is stopped and aligned in a defined manner at the position to be marked. Then the marking process starts. After marking, an ID reader is used for checking.

OneMark

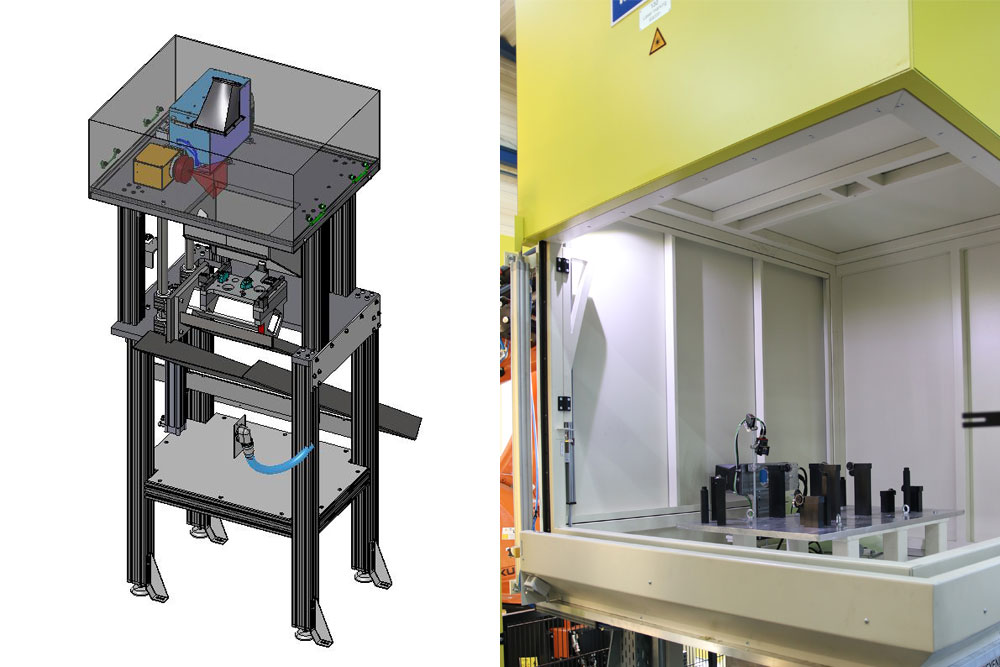

After loading the workpiece, a laser marking unit applies the corresponding code to the workpiece. The code is then read for inspection. Extraction and laser protection cabin ensure a safe working environment.

DualMark

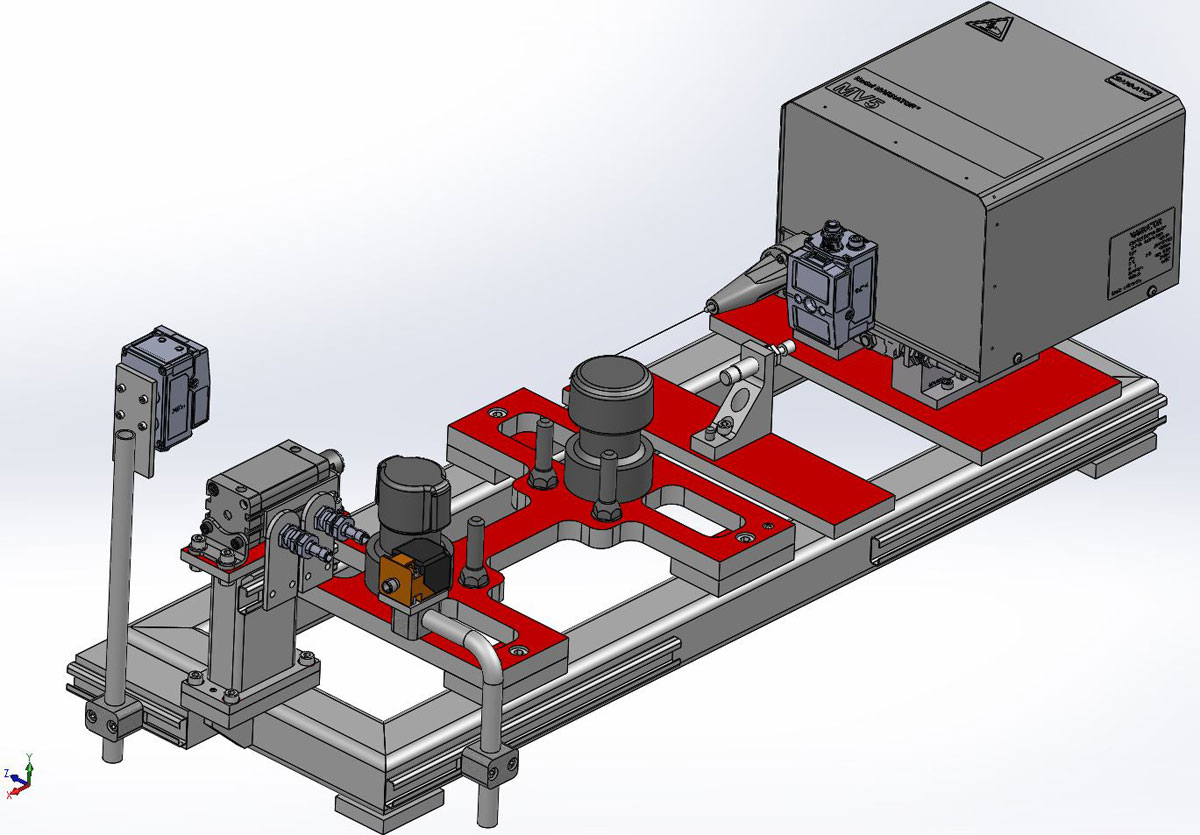

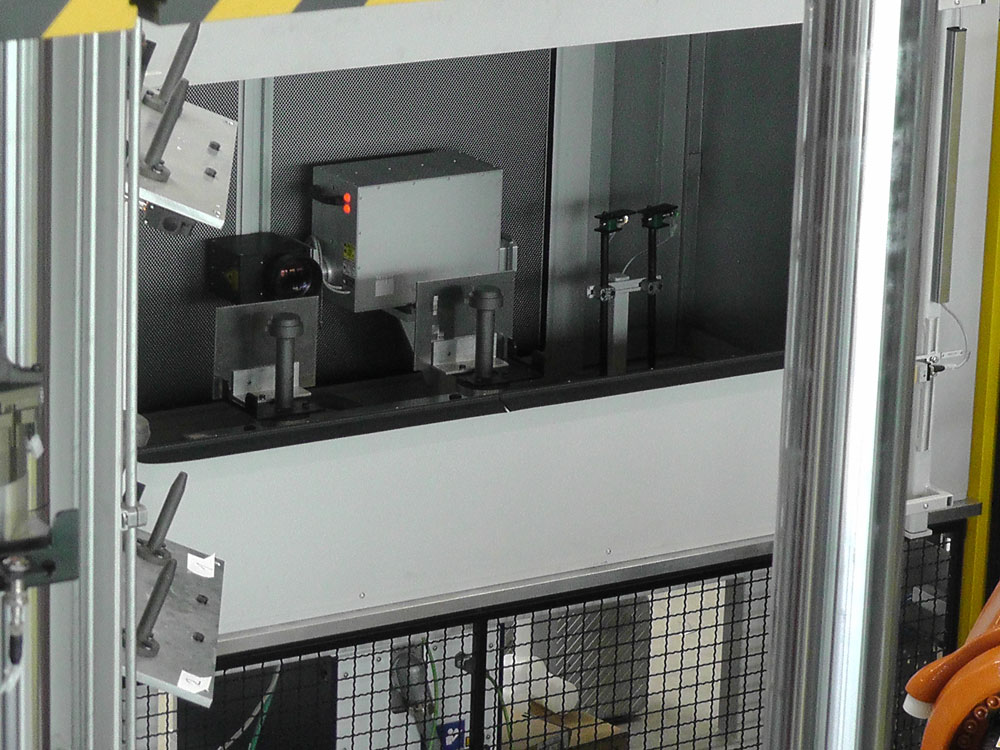

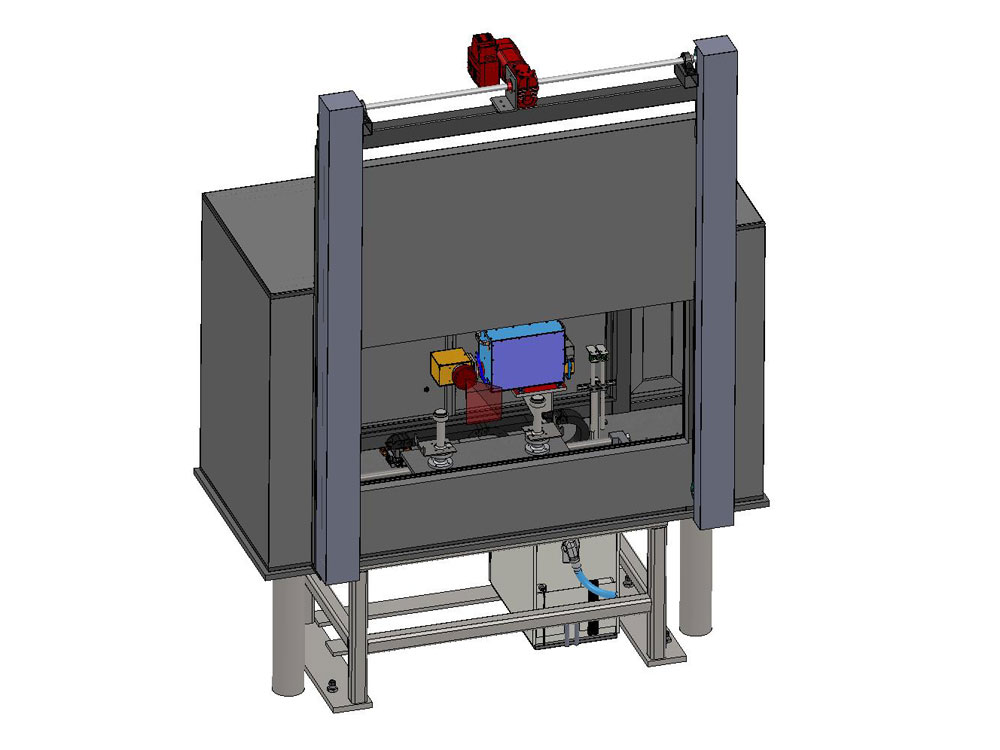

A linear axis positions the two workpieces in our DualMark Station at the position to be marked. This reduces the number of required laser heads to one laser head. Furthermore, only one loading and unloading process is required.

MultiMark

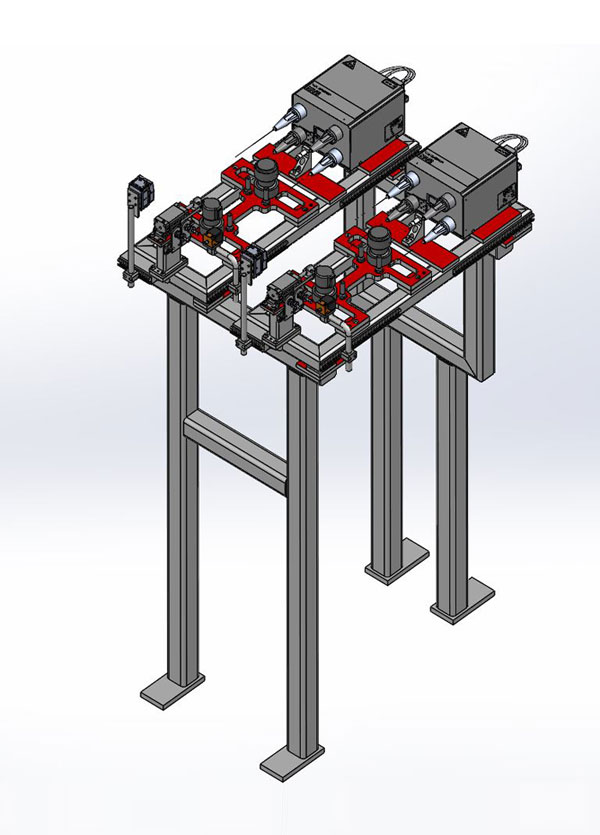

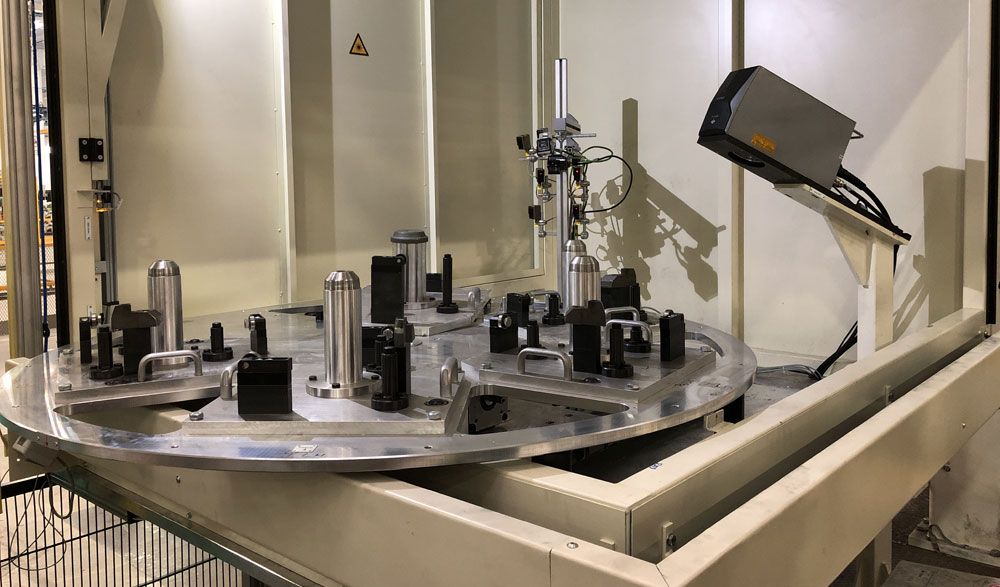

The MultiMark laser station checks the readability of the code and is equipped with a rotary table, which can hold several workpieces at the same time. The workpieces are precisely indexed to the position to be marked by the positioning unit. This reduces the number of required laser heads to one laser head. Furthermore, only one loading and unloading process is required.

The OCR station is equipped with a marking laser and with a 3D image processing system. With this, reading OCR characters is no longer an obstacle. Even characters with a height of only 1.3 mm are no problem. The read OCR code is transmitted to a higher-level control system and then converted into a DMC code and applied to the workpiece.

Combined with an intuitive touch screen user interface, setting up and teaching symbols is easier than ever.

Your contact for industrial marking