Internal feeders and casting systems that cannot be removed by sawing require a high cutting capacity. Our flexible machine concepts can achieve this. They also take over machining tasks for functional surfaces, such as drillings or tasks of pre-machining and finishing.

To achieve this, we develop different solutions for different machining tasks. Individual machining concepts enable exact and flexible fixing of your workpieces. Multi-axis machining stations with stationary or movable spindles solve your individual machining task. Our machines for metal cutting are available with central lubrication, internally cooled tools and the tools suitable for the machining task.

For wheel guide components, we offer various processing machines, such as drilling stations for the drilling of the bearings and steering axle. Among others, these machines are used for wheel carriers, wishbones, control arms and rear axles.

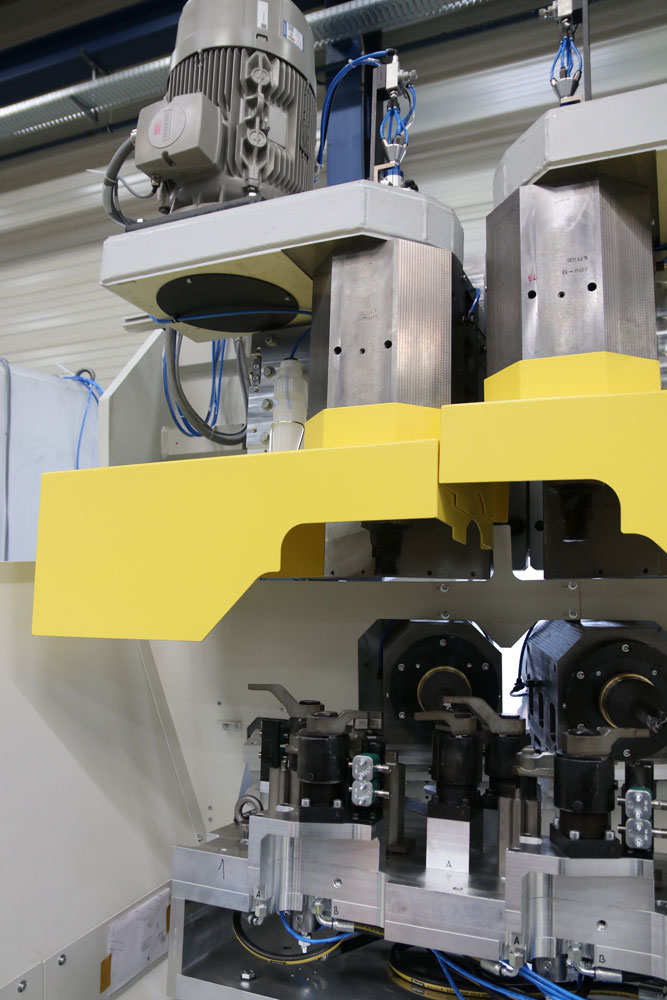

Processing stations for drilling and pressing of internal feeders on crankcases.

Five-axis processing machine with multi-spindle unit for drilling holes and valve cover bores.

Milling with industrial robots is a cost-effective alternative for machining tasks where the accuracy of a robot is sufficient. Thus, tasks of pre-machining can be taken over by our robot milling stations. This reduces the cutting capacity at subsequent machining centres and thus the investment costs. We rely on the advantages of both tool-guided and workpiece-guided solutions. Depending on the task, we offer you the appropriate solution. Individual fixtures and gripping systems enable flexible system concepts. In the case of workpiece-guided solutions, the robot also takes over the handling of the workpieces in addition to the machining task. This increases flexibility when using different tools and processing steps and reduces the number of robot systems required.

We have over 30 years of experience in robot processing. During this period, we have taken on a wide variety of machining tasks, such as

The machining of internal feeders occurs for example on chassis parts such as subframes. For this task the robot carries out so-called plunge milling on fixed or moving tool spindles. Depending on the feeder system, only partial machining may be necessary. The separated feeders are directed into collecting containers and separated from the chips produced.

Further information modular robot processing cell and drilling, sawing, milling:

Your contact for milling