When decoring or de-sanding castings, the sand core, core residues and adhering sand are reliably removed. This is done in the three process steps of hammering, vibrating and turning. Pneumatic hammers break the sand core in the first step by applying impact energy. The broken sand core is then crushed by high-frequency oscillating movements. This is done by crushing and breaking up the sand lumps on the casting wall. The removal of the moulding sand is achieved by vibration and a rotary movement of the casting. The rotary unit positions the casting in an ideal position for emptying. Blowing out can be supplemented by compressed air to keep the residual sand quantity as low as possible.

We gladly carry out decoring tests and pre-series for you at our test facility.

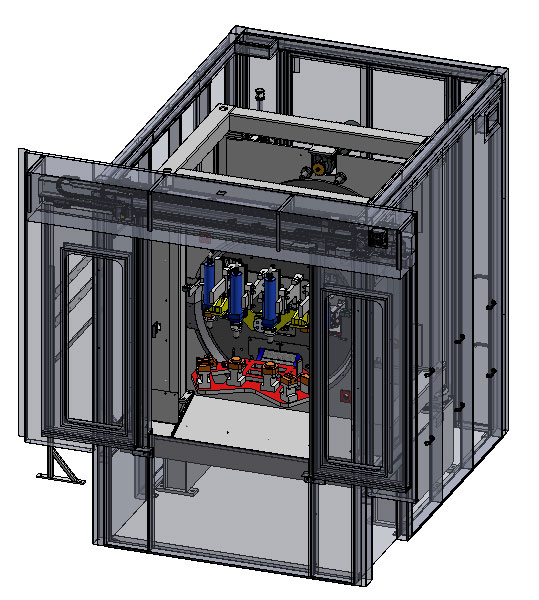

Our machines and stations for decoring are available as encapsulated systems on request. This reduces sand emission into the air. The cabins can be additionally vacuumed. The required extraction capacity is calculated based on a flow analysis. Noise emission and fine dust pollution can thus be minimised. This protects machines and plant components and ensures a quieter working environment.

We use containers, vibratory chutes, conveyors or discharge chutes for the removal of the sand produced for sand processing.

Among other things, our decoring solutions are suitable for:

Cylinder heads, engine blocks, electric motor housings, subframes, rear subframes, knuckles, heat exchangers, structural parts, pump housings, side members, transfer plates, end caps, differential axles, transmission housings and subframes.

Hammer stations are used for breaking the sand core as well as for pre-decoring and post-decoring. Our hammer stations are available with swivel-mounted, movable, rigid and lateral hammer units. According to your requirements and the geometry of the work piece, we design suitable devices. Our hammer stations can be integrated into fully automated systems. We develop suitable gripping systems for robot loading and unloading. The hammering process can be monitored by our monitoring system.

Our vibration stations enable the sand core to be pulverised by an oscillating movement generated by two unbalance motors. If it is not necessary to turn the casting, the positioning system can be omitted. Vibrating stations can be used with separate hammer stations or as post-decoring stations. Our vibration stations can be integrated into fully automated systems. We develop suitable gripping systems for robot loading and unloading.

Our 3-in-1 decoring unit combines the process steps hammering, vibrating and turning in one machine. Therefore, sand only accumulates at one point. Sand carry-over is thus reduced. Only one loading and unloading process is required for three process steps.

Compared to other manufacturers, we do not use complex gears for turning and vibrating. This solution makes our machine extremely robust and the susceptibility to errors low. Gearbox solutions are expensive when it comes to the procurement of spare parts and, in the event of failure, lead to longer plant downtimes.

In our 3-in-1 decoring machine, two powerful unbalance motors in counter-rotating operation ensure directed oscillation. The machine can be loaded and unloaded manually or with a robot. Standard interfaces such as PROFIsafe are available for system integration.

The 3-in-1 decoring unit is soundproofed and is equipped with a loading door that opens and closes automatically. The decoring machine can be equipped with up to four pneumatic hammers.

The individual decoring operations can be varied and programmed adapted to the casting. The decoring time depends on the casting and is, for example, approx. 46 seconds for two cylinder heads with double loading.

Our monitoring system enables the monitoring and recording of energy consumption (air consumption/power consumption), vibration values and hammer frequencies.

Our hammer monitoring system MH4 is available for frequency monitoring of pneumatic hammers.

The hammer monitoring system monitors the frequency of the pneumatic decoring hammers. The system ensures a secure and documented hammering process in hammer stations as well as combined decoring machines and can be easily integrated into existing plants.

Your advantages:

Functionality:

The hammer monitoring system monitors the frequency of four decoring hammers. The frequency is determined by evaluating the pressure curve in the exhaust air of each hammer. The analogue sensors are integrated as closely as possible in the exhaust air duct. By means of a powerful PLC, sampling rates of >750Hz are achieved. Due to the exact mapping of the pressure curve, frequencies between 10 and 30 Hertz are reliably displayed with a high measuring accuracy. Warning and alarm messages follow via the software if the pressure falls below defined limit values. The limit values can be parameterised either directly on the 4″ touch screen or via the Profinet interface. As a Profinet IO-Device, the hammer monitoring system additionally supplies the current as well as the average frequencies and is integrated via the GSDML file supplied.

Your contact for decoring