Robot-guided deburring is divided into tool guidance on the one hand and workpiece guidance on the other. For tool guidance, one or more machining spindles are mounted on the sixth axis of the robot. These can be motor spindles or tools driven by compressed air. The space requirement of this solution is smaller compared to the workpiece-guided solution. However, required tool changes may affect the cycle time of the cell.

In workpiece guidance, the workpiece is picked up by the gripping system of a robot. The robot moves the casting along fixed spindles, pneumatic tools and belt grinders. The workpiece guidance system enables a quick change of different machining stations. In addition to machining, the robot also performs handling tasks, such as loading and unloading feeding systems.

Compared with deburring presses, the robot is very flexible. If the contour of the workpiece changes, only a re-teaching of the machining path is necessary. When using a deburring press, the tool must be reworked in a complex way. This leads to high costs and requires a longer plant downtime. If a change of type is pending or if different workpieces are to be processed on the system, the tool must be replaced on deburring presses. The robot automatically receives the information as to which type of workpiece is pending. This enables a set-up in cycles and the processing of different types in one cell. With our flexible gripping systems, new workpieces can be set up automatically and in a cycle time neutral manner. In addition, the entire gripper can be exchanged with a gripper changing system.

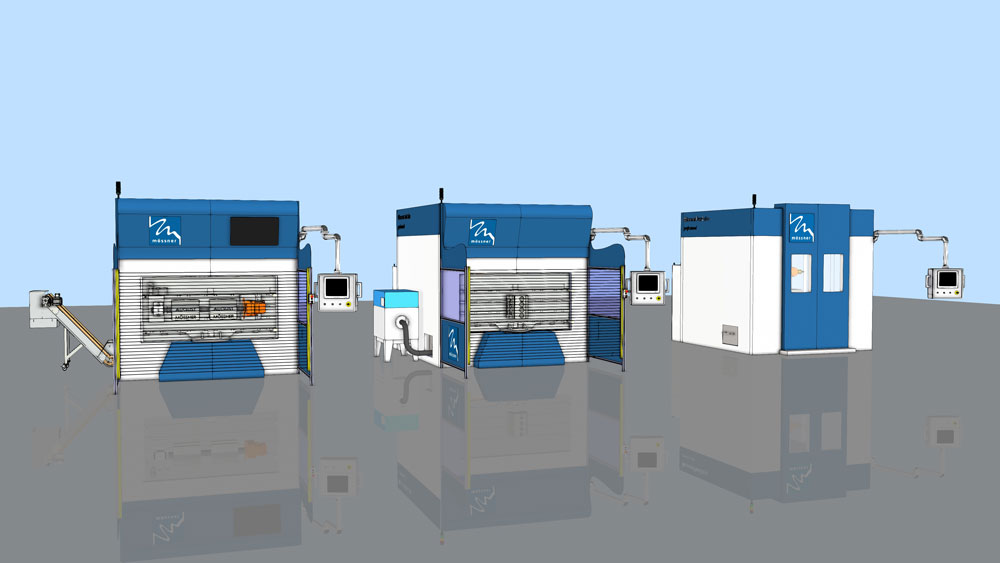

As a specialist for robot-based deburring, we have successfully integrated hundreds of systems worldwide. With our workpiece-guided solutions, up to five sides of the cast part can be reworked and thus automatically fettled.

The fettling is carried out on various driven tools such as

We use a wide range of milling tools for face milling, side milling and plunge milling. With or without indexable inserts, depending on the intended use. Spindles and tools are available with minimum quantity lubrication as internal cooling or spray heads.

Our machining spindles are ideally suited for high cutting performance and rough use in the foundry. Different performance classes allow different applications. The spindles are mounted on single-spindle or multi-spindle stations. Depending on requirements, these can be easily extended. Power, vibration and tool condition are monitored by means of suitable sensors.

Robot deburring is the ideal supplement to deburring presses. Areas that cannot be reached by the deburring press or only with great effort are plastered by the subsequent deburring with industrial robots.

For castings and forgings made of steel, we also offer solutions for grinding and deburring with robots, punch deburring, knock-off and cutting.

For high cutting capacities, our robot solutions offer inexpensive and flexible alternatives to expensive machining centres. Find out more under:

Your contact for deburring