Loading and unloading

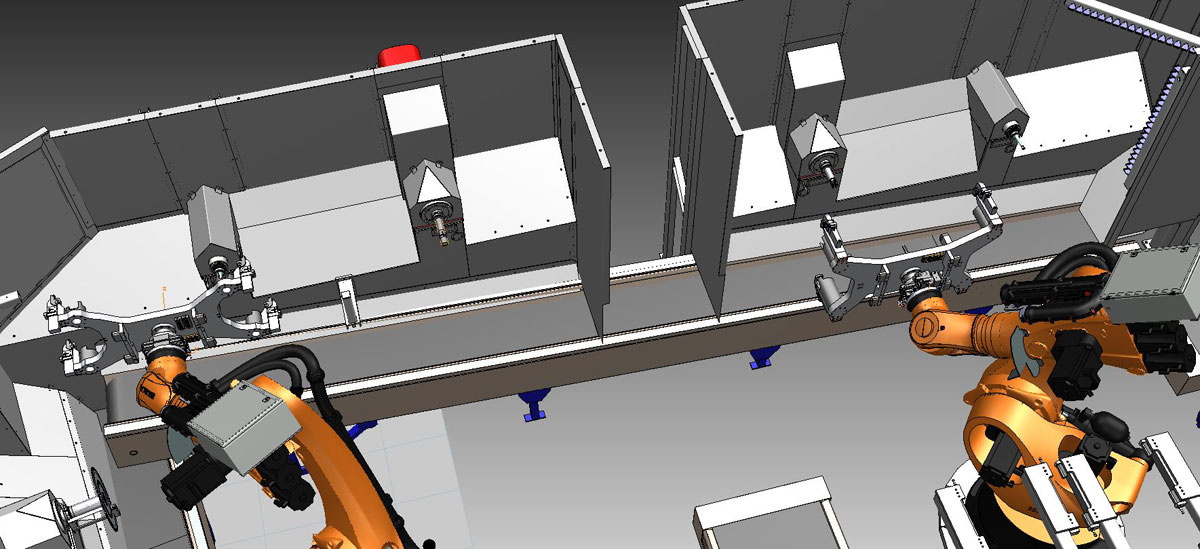

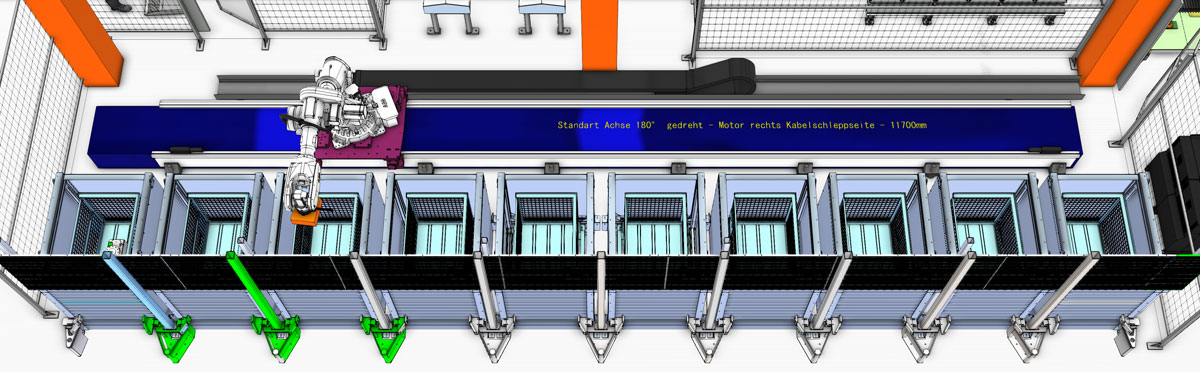

With our robot solutions we automate your loading and unloading process of various machines such as blasting machines or processing centres. Hereby, we take over the entire mechanical engineering as well as the com­missio­ning of the handling solution for you. By using linear units, the working area of the robot can be increased considerably. Thus, several processing centres or process steps in a row can be loaded and unloaded by one robot.

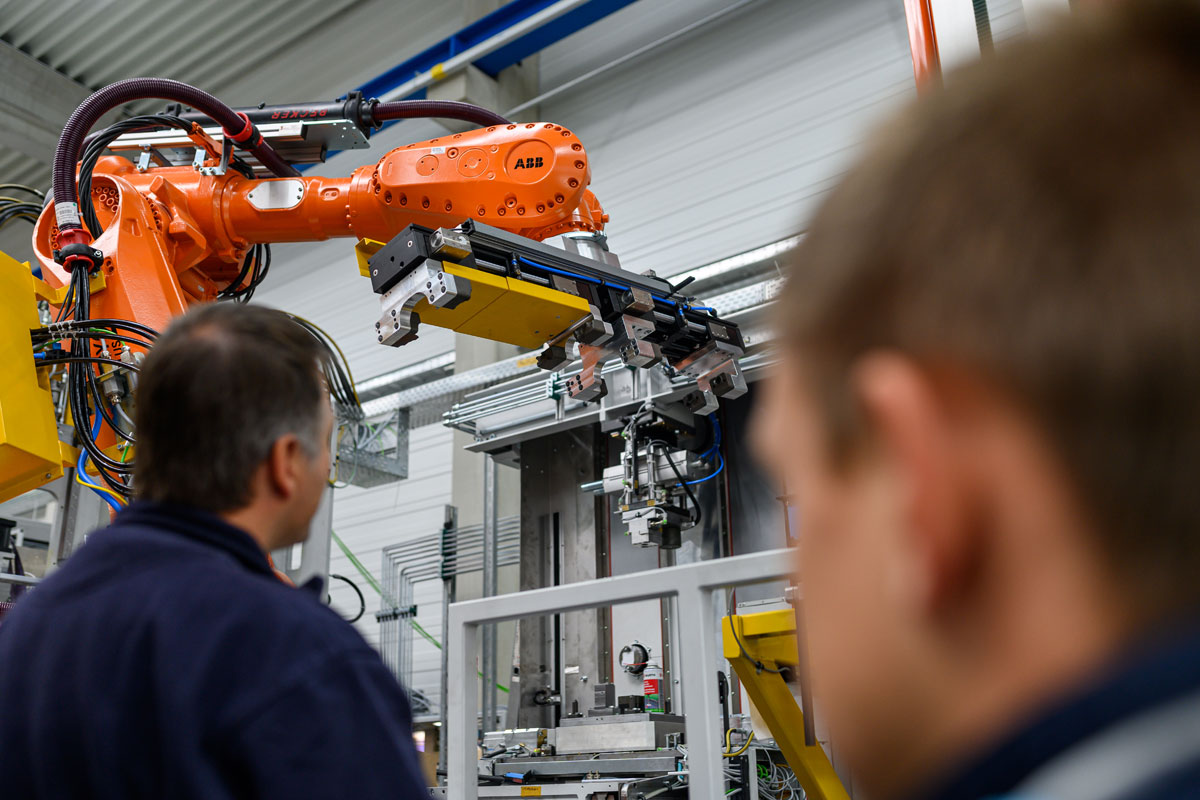

Palletising/de-palletising

We take over the programming of palletising tasks as well as the development, assembly and commissioning of your palletising station. With the help of gripping technology adapted to your requirements, our robot palletising stations enable efficient and flexible palletising of small and large workpieces. For this purpose, we use robots with a load capacity of up to 1,300 kilograms. Our palletising solutions are used in the palletising of finished workpieces even in rough environments such as the foundry industry.

Sawing

Milling

From the compressed air spindle to the 40kW motor spindle, we are your contact for robot milling. Depending on the task at hand, we use the advantages of the robot-guided tool or the workpiece guidance. In the latter case, the robot also takes over the handling in addition to processing. The advantages of using a robot for cutting processes are in particularly the flexibility and the lower asset costs compared to a processing centre. The long range of industrial robots reduces investment costs, especially when processing large-volume workpieces. Further advantages are also offered by the combination of industrial robots and processing centres. The robot takes over the loading and unloading of the processing centre. During the process time, the industrial robot deburrs the workpiece or carries out the pre-processing. This reduces the process time of the process centre and lowers investment costs. In addition, manual reworking processes can be avoided, personnel costs saved, and consistent quality achieved.