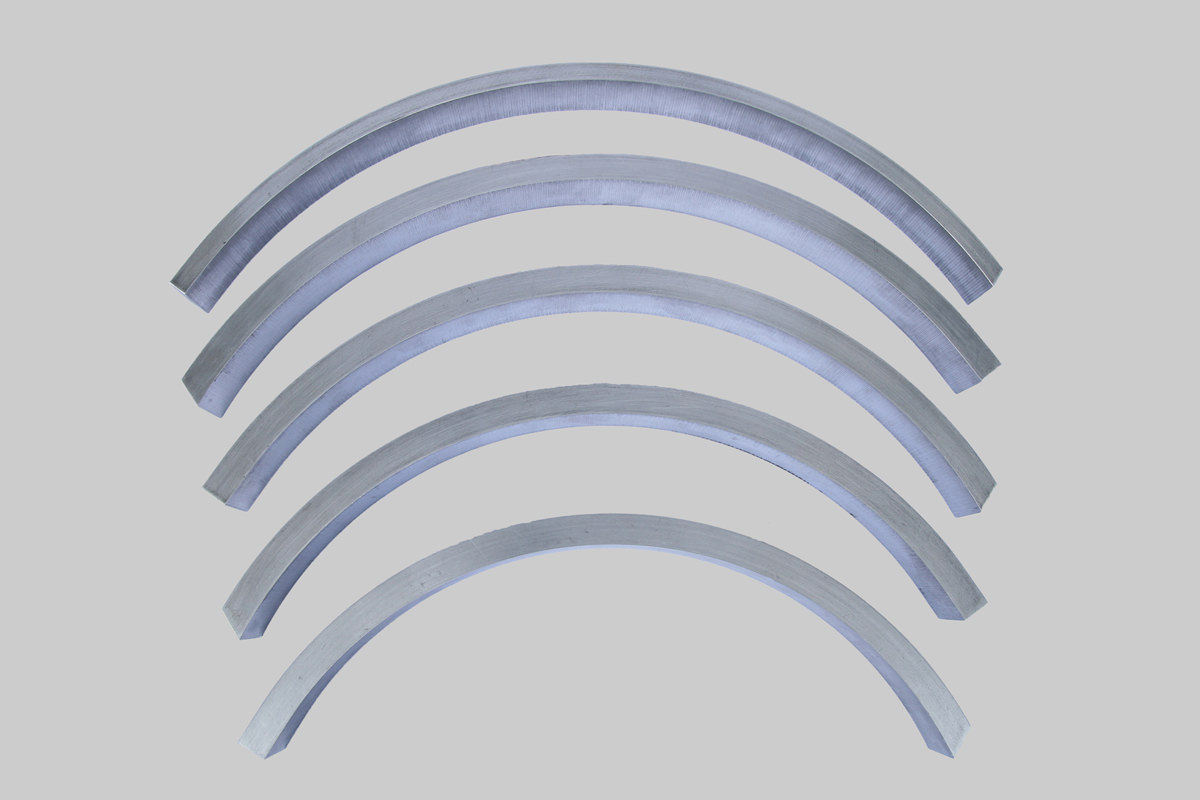

Contoured cuts

Contoured cut

The Mössner band saw machines for contoured cuts can be controlled numerically (X axis) and can be rotated numerically about the saw cut line (C axis). Through the numerically controlled delivery of the workpiece (Y axis), any contours can be sawed in plates and blocks. The coordinate transformation for the current calculation of the three axis values (X, Y, C) is carried out directly in the control system and allows simple contour programming with XY coordinates. Additional features are, for example, a fully automatic part supply system, a waste and chips disposal system, a compacting system, a part transport system and a protective cabin.

Typical process:

Technical data of the system: